TUTCO CONDUCTIVE

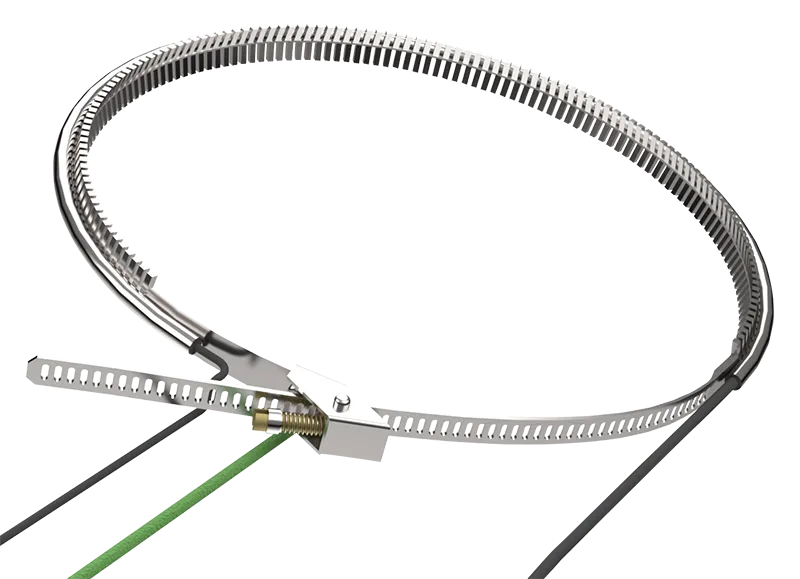

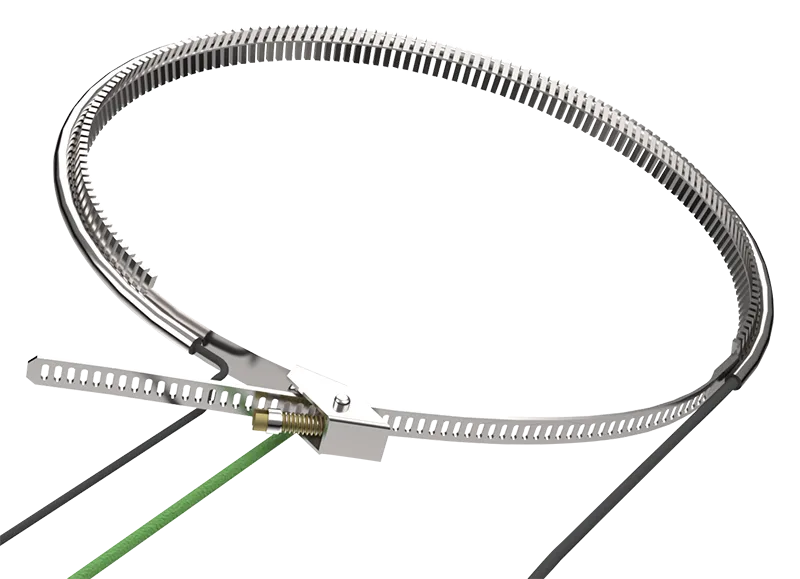

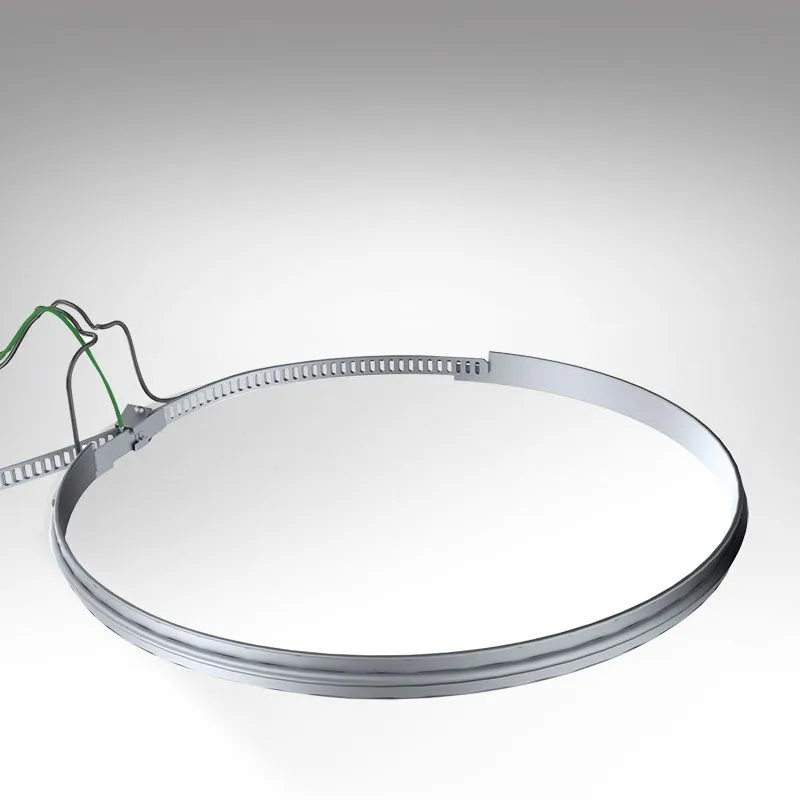

Belly Band Crankcase Heaters

The migration of liquid refrigerant to the compressor is a common phenomenon in refrigeration and air conditioning systems. When the refrigerant mixes with oil and the compressor starts, it can lead to oil slugging. This causes the mixture to foam violently, forcing most or all of the oil charge out of the system. As the compressor attempts to pump the liquid—something it is not designed to handle—it can result in broken valves, damaged pistons, and blown head gaskets. By optimizing the temperature of crankcase oil, our Belly Band crankcase heater helps protect the compressor from refrigerant migration. Oil is kept as much as 30°F warmer than the system temperature, and refrigerant is forced to remain in the condenser, evaporator, or accumulator. TUTCO’s Specialty Crankcase Heaters snugly encircle the compressor housing to provide positive, highly efficient transmission of heat. Acting as a heat sink, the crankcase can then absorb and transmit heat directly to the oil. Heat loss to ambient air is greatly reduced along with the major cause of refrigerant migration.

FEATURES AND BENEFITS

- Corrosion resistant exterior

- High temperature silicone rubber element rated to 230°C

- PVC insulated lead wires rated at 105°C

- VW-1 rated lead wires

- Custom leads and terminations available

- Voltages through 600 V ac

- Wattage for each model matches compressor requirements

- Completely moisture proof

- Quick and easy installation

- Nominal power consumption due to highly efficient heat transmission and low wattage

- Air Conditioners

- Refrigeration

APPLICATIONS

Frequently Asked Questions

When the compressor is off and the site is cold, refrigerant vapor can drift into the crankcase, condense in the oil, and dilute it. That diluted oil loses its ability to lubricate effectively. Upon startup, you risk slugging (liquid entering the compressor), oil wash‑out, and parts damage like broken valves or pistons. The belly‑band heater keeps the oil warm enough that refrigerant stays in the condenser, evaporator or accumulator—not in your oil. By maintaining the oil at a higher temperature than the shell, the heater acts as a safeguard for your compressor.

Yes—this style is particularly useful in cold‑climate or outdoor installations because it provides closer and more consistent heat transfer to the crankcase. That said, you should select a model that’s built for the environment: look for corrosion‑resistant exterior materials, silicone rubber or other high‑temperature elements rated for low ambient temps, and properly rated lead wires and terminations to handle moisture, vibration or freezing conditions. Choosing the right model ensures your compressor starts reliably even when temperatures drop.

A proper installation means the band heater sits flush against the compressor shell—no gaps, no weld beads under the strap, and good contact around the circumference. The heater should be mounted before the first startup (or after long storage) so the oil has been held warm. Also check that the lead wires and terminations are well protected and secured, and that the strap is tensioned properly—loose mounting or exposure to vibration can undermine performance and reduce heater life.

The belly‑band style wraps snugly around the compressor housing, which means it transfers heat more efficiently into the oil inside the crankcase. Because it hugs the body like a band, it reduces heat loss to the ambient air and helps keep the oil consistently warmer than the coldest parts of the system. This is especially important in systems where liquid refrigerant tends to migrate into the crankcase during off‑cycles. With a belly‑band heater, you’re actively preventing that migration and protecting the compressor from damage when it restarts.