TUTCO CONDUCTIVE

Tubular Heaters

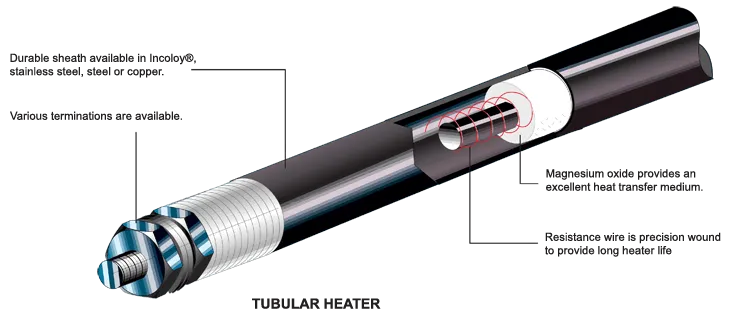

TUTCO Tubular Heaters can be custom-formed into a wide range of shapes that perfectly meet your specific requirements of any application. Incoloy 800, Incoloy 840, 304 Stainless Steel, 316 Stainless Steel, 321 Stainless Steel and Coated Carbon Steel sheath materials are available, as well as a large selection of termination styles. Magnesium oxide (MgO) insulation ensures superior heat transfer, and the resistance wire is precision-wound for long heater life.

FEATURES AND BENEFITS

- Custom-formed to meet specific requirements

- Incoloy 800, Incoloy 840, 304 Stainless Steel, 316 Stainless Steel, 321 Stainless Steel and Coated Carbon Steel sheath material available

- Superior heat transfer

- Available in 0.260, 0.315, 0.375, 0.430, 0.475 & 0.625" diameters

- Variety of lengths available • USA or global manufacturing options

- Vibration and contamination resistant

- Finned tubular elements are available, Consult factory

- Consult factory for special sizes and feature not listed here

- Contact factory with forming requirements

APPLICATIONS

- Platen Heaters

- Packaging and Sealing Bars

- Food Grade Sealing/Wrapping

- Food Service Warming

- Refrigeration

- Holding Tanks

- Drum and Barrell Heaters

- Incubators

- Textile Processing

- Chemical Processing

- Laboratory Warmers

- Scientific Testing Equipment

- Glass Processing

- Deicing

- Defrost Heaters

- Railway Heating Applications

- Space Heaters for Public Transport

Frequently Asked Questions

TUTCO tubular heaters are used in a broad range of applications — from plastics (platen heaters), packaging, food-service (sealing, warming), agriculture (drum/barrel heaters), process (chemical, textile, lab equipment), to deicing/railway/public-transport heating. When specifying a heater, consider: the medium you’re heating (air, liquid, surface), the operating temperature and maximum sheath temperature, the mounting or immersion conditions, any vibration or contamination exposure, and whether you need special features (finned elements, special terminations, custom bends). Industry guidance emphasizes that matching heater type (straight, U-shaped, finned, etc), sheath material, wattage and environmental conditions are critical for good performance.

Yes — one of the key advantages of TUTCO’s tubular heaters is that they can be custom-formed into almost any shape to meet your unique requirements. Whether you need a U-bend, an L-shape, a full coil, or some specific contour to match your equipment, we can accommodate that. Just provide your forming requirements (bend radius, dimensions, mounting style) and we’ll work with you. As many industry sources note, the flexibility of tubular elements is one of their major benefits.

At TUTCO, you can select from a wide range of sheath materials for our tubular heaters — including Incoloy 800 and 840, 304, 316 and 321 stainless steels, and coated carbon steel. The right material depends on your application’s environment: for example, if you expect exposure to corrosive chemicals or high temperatures, a higher-grade alloy (like Incoloy or a stainless) is a better choice. If cost is a primary concern and the environment is mild, coated carbon steel might suffice. By choosing a material suited to your conditions, you’ll get better durability and performance.