Control Panel Environmental Protections

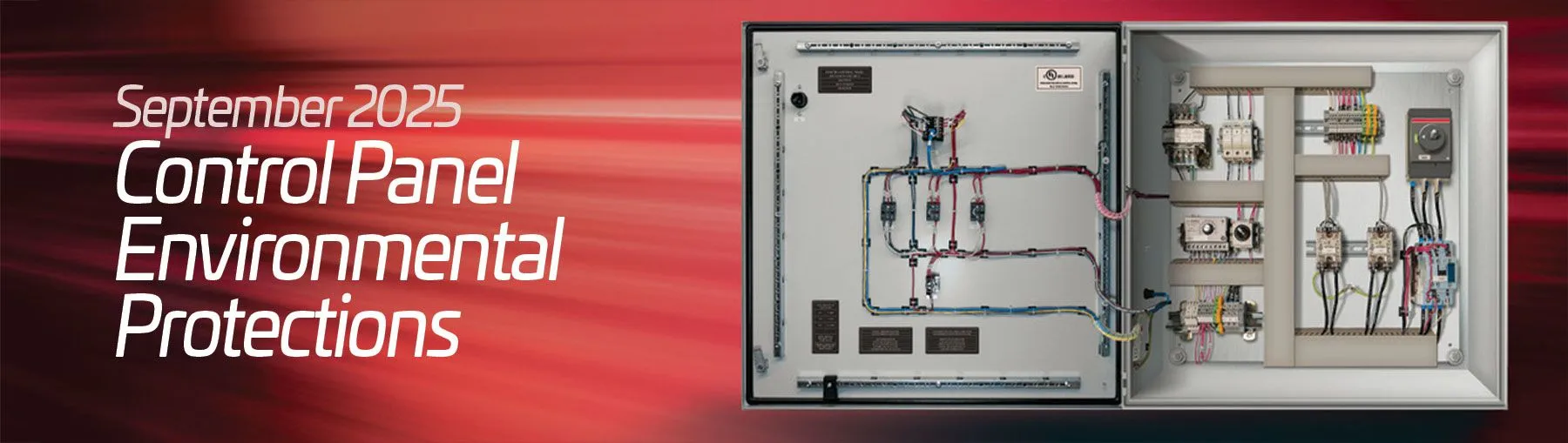

Whether installed on a factory floor, tucked under a canopy in a shipping yard, or fully exposed to summer heat and corrosive air, control panels must maintain integrity while providing dedicated control. At TUTCO Farnam, understanding—and engineering for—environmental exposure is a critical part of the panel design process.

While many in the industry refer to NEMA ratings—such as NEMA 12, 4, or 4X—TUTCO Farnam builds to the UL 508A standard, which aligns closely with NEMA but adds additional third-party oversight and component verification. Every panel component is UL-Type Rated for its specific environmental use, ensuring that what’s installed matches the application.

For customers operating internationally, TUTCO Farnam prefers the IP (Ingress Protection) standard, common in Europe and other regions. Our engineers translate that requirement into an equivalent UL Type Rating classification to ensure the required compliance.

The panel’s environment can dictate its design. Outdoor installations come with additional challenges—sun exposure, precipitation, temperature swings, and even corrosive chemicals or gases. One of the first questions TUTCO Farnam asks: Where is the panel going, and what will it be exposed to?

Outdoor, open-air locations may require sunshades, drip hoods, or an AC unit. Sheltered environments, like those under a shed or roof, may require less shielding but still demand attention to temperature and humidity. Corrosive environments will shift the requirement to UL Type 4X, which calls for stainless steel enclosures that can handle corrosion. Hazardous gases which may be explosive may necessitate a completely different UL classification.

Temperature is often the most critical and overlooked factor in producing a control panel. TUTCO Farnam’s panels are rated to operate in environments from 5°C (41°F) up to 40°C (104°F) in order to maintain the UL standard. That is the internal temperature and includes the heat coming off of the internal components. As the amperage of the controller increases, the components generate more and more heat.

Sharing information about your process and the environment your controller will operate in is essential. TUTCO Farnam works closely with customers to determine load profiles, peak temperatures, and environmental conditions so that each panel remains compliant—and reliable—under actual operating conditions.

One of the Worst Things for a Heater is Heat

There are three things that are worst for your electric heating element, heat being one of them.

by Ian Renwick

I'll cut right to the chase and then discuss each one. The three worst things for your electric heating elements are:

- Contamination

- Physical Abuse

- Heat!

Contamination can be bad for a heater if it's not properly planned for. Did you plan for water to splash on your heater? How about molten plastic? Cheese? All these contaminants can cause a bad day for your heaters, either immediately or over a period of time. To a good extent, heaters can be built to combat the common types of contamination they might be expected to endure but without proper planning, it may turn into a bad day.

Convoluted armor, for example, is completely waterproof. Liquid can't get through it. Square-Lock armor, on the other hand, is not waterproof. If you have an application where a wash-down occurs, you might want to consider going with convoluted armor to protect the leads from moisture. That water-proofness is what makes convoluted armor less flexible than square-lock armor, and unfortunately more expensive.

Teflon leads? Use them over mica insulated leads if things are going to get wet, but make sure the lower temperature rating (250°C vs. 450°C) is acceptable.

Does your heater need a special seal on it (where the leadwires exit) to keep contamination out? Try an epoxy seal, or RTV, or a swaged in Teflon plug. They all offer moisture resistance whereas a regular cement seal does not.

Make sure to consider the location of your heater and what they might be subjected to.

When it comes to physical abuse of a heater, there are two types, the intended and unintended kinds.

Don't try to make your heater's leads reach that extra 1/2" to make a connection in your control box by talking yourself into them being able to stretch. Don't carry a heater by its leads. Don't yank on heater leads, ever. When installing a band heater, don't flex it just a little bit more to fit it over the pipe you need it on because you can't be bothered to remove the other band heaters on the pipe so you can slide it over the end. Don't hammer a heater in place or flatten part of it just to give your equipment that extra 1/4" of clearance it needs. Those are examples of intended abuse.

The most common unintended abuse is flexing leads. Repetitive flexing of leads in an application (especially high-speed sealing applications) might work fine today and tomorrow, but eventually they'll break off. In situations like that, try to minimize the flexing by making the leads as long as you can, having them drape somewhere in a few loops as they rest on a surface. Any machine movement will then move the leadwires in the loop (gently) and stress the connection point less.. That'll lead to longer heater life because the connection won't be under so much stress and strain.

Heat is bad for a heater? These heaters are supposed to get hot, aren't they? Yes, but heat is a killer. Heat can be detrimental to heaters in two ways. It reduces the dielectric strength of needed insulators inside the heater, and it causes internal metal components to oxidize. The dielectric strength of any insulator goes down as temperature goes up. It's just one of those things that you cannot escape from, and it shouldn't be ignored.

Dielectric reduction and eventual breakdown occurs when the voltage between live parts and grounded parts (like the heater sheath) is sufficient to allow current to conduct through the dielectric material or spark through it. The higher the temperature, the more the dielectric strength is reduced, and the more likely failure is to occur.

The other failure mode occurs when things oxidize. The metal parts of the heater, be it resistance wire or the internal surface of the heater sheath form an oxide layer (think rust) on them because of the presence of air inside the heater. Heaters that are either swaged or have aluminum oxide insulation have less air in them and oxidize less than heaters that aren't swaged or have phlogopite mica or muscovite mica insulation in them. That's why those heaters (the ones that aren't swaged or have mica insulation) can't be operated at such a high watt density or temperature as the other product lines that contain less air. As an oxide layer forms, it grows in thickness over time, effectively bringing conductive and grounded surfaces closer and closer to each other. Eventually they get so close inside the heater that the insulation material can't offer enough resistance and failure occurs.

So how do you combat this? The first step is to operate heaters as coolly as possible. If you do need to operate at high temperatures make sure a cartridge heater is inside a tight-fitting hole or that a band heater is tightly clamped in place. It is often a good idea to retighten band heaters once they get to temperature (or near to it) because band heaters tend to get a little loose because of thermal expansion of the band heater itself. They do indeed get bigger the hotter they are. Be sure to make safety your top priority when retightening a hot band heater. That's a very important point to consider.

When a cartridge heater is in a hole tightly, or a band heater is good and snug once at temperature, conductive heat transfer is king and it's the best condition for heat to get away from a heater and into what needs to be heated. When you're in that situation heat is getting away from the heater as best it can, preventing heat from building up in the heater and thereby causing its temperature to increase. If heaters are loose, then there's more convective heat transfer which is really terrible in comparison to conduction. If the heat can't get away from a heater, the temperature of the heater can only do one thing; increase.

So, the title of this article is a little misleading. It's not necessarily heat that kills heaters, it's temperature. Heat with nowhere to go causes the temperature of a heater to increase and it's the temperature of materials that cause them to change, to either breakdown in the case of insulation, or oxidize in the case of metal parts.

Treat your heaters well and they'll return the favor. Treat them poorly, (and there are many ways to do so) and they won't be your friends for very long.

Everything Changes: A Transition and New Adventure!

by Jeff Elrod

I have been a TUTCO employee for 28 years now. In that time, the only thing that has always held true is everything changes. I have written in this series of articles over the last few months about how TUTCO has evolved since it was first started. On a personal level, since I started at TUTCO, I have seen us transfer from a supplier of complete package units and duct heaters for the commercial HVAC market and smaller strip heater assemblies for the residential HVAC and appliance markets to basically a one-stop heat shop—expanding the existing markets with both offering and value-add, but also adding a comprehensive industrial heat offering and now adding the capabilities to build UL508A industrial control panels for both heat and non-heat applications. While we do not like to and do sometimes have limitations, as a company we do not want to say no, we cannot build that.

I have been a TUTCO employee for 28 years now. In that time, the only thing that has always held true is everything changes. I have written in this series of articles over the last few months about how TUTCO has evolved since it was first started. On a personal level, since I started at TUTCO, I have seen us transfer from a supplier of complete package units and duct heaters for the commercial HVAC market and smaller strip heater assemblies for the residential HVAC and appliance markets to basically a one-stop heat shop—expanding the existing markets with both offering and value-add, but also adding a comprehensive industrial heat offering and now adding the capabilities to build UL508A industrial control panels for both heat and non-heat applications. While we do not like to and do sometimes have limitations, as a company we do not want to say no, we cannot build that.

I write this article as I go through a change in my professional life. I spent the first 20 years with TUTCO working for the Packaged Heat Division, working primarily in the commercial HVAC and duct heater products as a design engineer. I then transitioned into the industrial heat realm, working with the Conductive Heat Group for the last 8 years mainly as a design engineer, but also started blending in some Sales Engineer functions. Then in March, I started transitioning over to the Farnam Custom Products Division as a Sales Engineer, becoming full time on August 1st. I will still be supporting the Conductive products and even the commercial HVAC as needed. I am also working to understand not just the Farnam products but all our industrial products so we can offer the best TUTCO solution to any situation. I like to call this my new adventure!

As humans, we often resist change, and I agree that change for the sake of change is not good, but we do have to change to grow. George Bernard Shaw once said, “Progress is impossible without change, and those who cannot change their minds cannot change anything.” Progress requires change. John F. Kennedy said, “Change is the law of life. And those who look only to the past or present are certain to miss the future.” To grow, we have to meet the challenges of that change, good or bad, because most times we cannot stop it. As John Maxwell once said, “Change is inevitable. Growth is optional.” The ability to change is a choice, and how we handle that choice says a lot about us. Albert Einstein said, “The measure of intelligence is the ability to adapt to change.”

I have said all of this to say TUTCO is changing and hopefully making everything better for our partners, because we do not want customers—rather, we want to be your electric heat partner. We want to work with you to supply one of our standard products or a custom one-off solution of not just an electric heater, but rather an entire heat system as the solution to your entire problem—not just being a small part or component of the solution. As your company changes and evolves, let us help you with Engineered Heat Solutions and then some. Let us use our centuries of technical expertise to “Think Outside the Box” for your application.

FEATURE APPLICATION

Climate Control

How TUTCO Heaters Make a Difference in a Wide Range of Applications

Managing air, temperature, and moisture is about more than comfort — it’s about safety, efficiency, and protecting sensitive equipment or products. From museums and hospitals to modular shelters and industrial production lines, TUTCO Farnam and TUTCO SureHeat heaters are helping organizations achieve reliable climate control in even the most demanding environments. TUTCO Farnam designs and builds custom air heaters for a wide range of HVAC applications, including air curtains, clean rooms, Environmental Control Units (ECUs), Auxiliary Power Units (APUs), bed bug treatment, and dehumidification. Every heater is engineered to customer specifications, ensuring accurate temperature control, energy efficiency, and long-lasting performance. TUTCO SureHeat adds another layer of capability with its high-performance process air heaters. Models like the Jet and Max deliver air temperatures up to 1,400°F (760°C), ideal for high-temperature regeneration, rapid drying, or any application that demands precise, reliable heat.

Supporting Sustainable Climate Control

As industries shift toward greener practices, TUTCO is helping clients transition to electric or hybrid HVAC systems. The company’s open-coil electric heaters are designed to optimize efficiency, reduce carbon impact, and integrate seamlessly into modern climate control systems. Applications Across Industries TUTCO heaters are versatile, supporting a variety of environments:

- Specialty HVAC: Modular shelters, portable HVAC units, mini HVAC, ECUs, air curtains, clean rooms.

- Sanitation & Medical: Bed bug treatment, surgical units, warming cabinets, delicate manufacturing.

- Restoration & Drying: Flood remediation, job-site drying, pharmaceutical manufacturing, wafer fabrication, plastics processing, paint booths.

- Temperature-Sensitive Environments: Cold storage, museums, libraries, hospitals, supermarkets, laboratories.

Whether it’s dehumidification, freeze protection, cleanroom conditioning, or portable HVAC, TUTCO Farnam and SureHeat heaters combine precision, durability, and scalability to deliver reliable climate control. No matter the challenge, our solutions fit the application, improve efficiency, and support sustainable practices.

FEATURE VIDEO

Band Heaters

TUTCO’s band heaters are designed to deliver precision, durability, and versatility across a wide variety of cylindrical applications, from plastic processing to scientific testing. In our newest video, members of the TUTCO band heater team—representing sales, engineering, and customer service—come together to share their expertise and insights. They walk through the different types of band heaters available, including HT Mica Bands, MI Better Bands, Permaheat Bands, and Ultima Bands, all manufactured in the USA. The conversation explores the unique capabilities of each product line, highlighting where and how they can be applied to solve real-world heating challenges. The team also discusses lead times, production processes, and the customizable options that allow us to engineer solutions for even the most demanding environments. Whether you’re looking for a standard band heater or a tailored solution, this video offers a closer look at how TUTCO’s experience, innovation, and commitment to customer success come together to support your heating needs. More on Band Heaters