Pneumatic Delivery Systems and Enclosure Heaters

Outdoor enclosures face unique challenges every day. Freezing temperatures, condensation, and moisture can damage sensitive electronics, control systems, and other components, often leading to downtime or costly repairs. The key is not waiting until problems arise: it’s preventing them before they ever happen. No matter the size of the enclosure—whether it is small enough to fit in your hand or large enough for a few people to fit inside—maintaining a controlled internal environment is critical for reliability. The type of heater you choose depends on the size of the enclosure and the thermal demands of what’s inside. For smaller enclosures, flexible silicone rubber heaters are an ideal choice. They provide excellent heat transfer, can be produced in custom shapes and sizes, and are perfect for preventing freezing or condensation in compact enclosures such as pneumatic delivery systems or small control boxes.

Pneumatic Enclosures: Why the Heating Strategy Matters

Pneumatic systems depend on clean, dry, temperature-stable air to operate correctly. Any condensation inside a pneumatic enclosure can lead to seized valves, erratic control responses, pressure instability, or corrosion of fittings and sensors. Outdoor pneumatic tube systems, drive-through transaction tubes, material-handling pneumatics, and remote air-actuated devices are particularly vulnerable because cold temperatures pull moisture out of the air supply and freeze it onto internal components. A properly heated pneumatic enclosure prevents:

- Valve freezing, which can halt transport systems or cause delayed actuation

- Moisture buildup that compromises air quality and clogs filters

- Sensor drift caused by temperature swings

- Premature wear of seals, regulators, and solenoids

- Pressure fluctuations triggered by thermally unstable air

Small, form-fitting silicone rubber heaters excel here because they can be adhered directly to metal manifolds, air reservoirs, or control plates, ensuring the air-handling system remains above dew point. For enclosures with internal air movement or multiple pneumatic components packed into tight spaces, a compact conductive-style heater paired with a simple thermostat ensures uniform temperatures and predictable pneumatic performance.

Medium-Sized Enclosures

For medium-sized enclosures, many may already include fans for cooling, which can be paired with a heater to distribute warmth efficiently. A basic thermostat can automatically activate the heater when temperatures drop below 32ºF and shut it off once internal air reaches 50ºF. This simple arrangement prevents environmental swings that would otherwise lead to condensation inside pneumatic regulators, solenoids, or electronics used to control air sequencing.

Large Enclosures and High-Performance Systems

Larger enclosures may require more sophisticated solutions. Crossflow blower heaters can be mounted directly to fan exhausts, ensuring heat is evenly circulated throughout the enclosure. Available in multiple standard lengths and customizable wattages and voltages, these heaters give OEMs and system designers the flexibility to achieve consistent, safe, and reliable forced-air heating. In systems where pneumatic equipment is installed alongside electronics, even distribution is crucial for keeping both air components and sensors stable.

For areas that are especially difficult to heat, finned strip heaters deliver targeted warmth to critical components. These heaters maintain localized temperature control for sensitive modules such as pneumatic regulators, flow meters, and valve banks where cold spots can cause erratic behavior. TUTCO’s finned strip heaters provide excellent heat transfer through forced air or conduction, making them a strong option for larger or vertically oriented enclosures. By combining these solutions, even the most complex enclosures—especially those integrating pneumatic actuation—can be fully protected from freezing, condensation, and moisture-related issues.

TUTCO heaters are used in a wide variety of outdoor applications, including ATMs, fast-food transaction drawers, pneumatic tube transport systems, security cameras, highway traffic signs, car wash controls, pump houses, and outdoor control panels. They protect against condensation, corrosion, circuit failure, water vapor, freezing, and temperatures dropping below operational limits.

At TUTCO, we have the heating solutions necessary for any enclosure size or application. Some models are available with minimum order quantities as low as 10 pieces. For OEMs, we offer custom, plug-and-play solutions designed to integrate seamlessly into pneumatic control cabinets, transport systems, and other enclosure types.

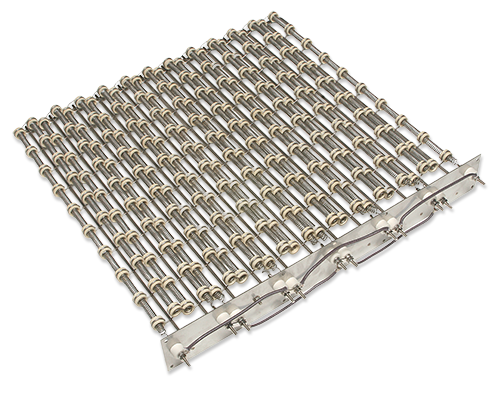

FEATURE PRODUCT

TUTCO Farnam Industrial Duct Heaters

The Power Behind Industrial Airflows

When most people hear “duct heater,” they picture HVAC equipment quietly warming homes, offices, or retail spaces. And that makes sense — TUTCO produces more HVAC duct heaters than anyone in the world. But beyond comfort heating lies a very different category with very different expectations. Industrial duct heaters are engineered for rugged environments, higher temperatures, faster response times, and the kind of reliability OEMs demand when air is a critical part of their process.

When most people hear “duct heater,” they picture HVAC equipment quietly warming homes, offices, or retail spaces. And that makes sense — TUTCO produces more HVAC duct heaters than anyone in the world. But beyond comfort heating lies a very different category with very different expectations. Industrial duct heaters are engineered for rugged environments, higher temperatures, faster response times, and the kind of reliability OEMs demand when air is a critical part of their process.

TUTCO Farnam industrial duct heaters can deliver temperatures up to 800°F (or higher with a custom solution) while maintaining low pressure drop and fast thermal response. Their open-coil design is simple but incredibly effective: air passes directly across the coils, providing immediate heat transfer while keeping the wire relatively cool. That means fast warm-up, fast cool-down, and efficient airflow without putting unnecessary strain on your blower system. These industrial heaters prioritize throughput, uptime, repeatable results, and integration into larger systems that run nonstop.

Our industrial duct heaters are available in standard square sizes including 6”, 12”, 13”, 22”, and 36”, but customization is extremely common. Larger heaters are also available and we build them regularly for OEMs whose applications demand very specific geometries. Many customers also run heaters in series—four banks of 10 kW, for example—creating modular stages that provide redundancy as well as flexibility. If one bank ever faults, operators can reduce airflow, maintain exhaust temperature, and swap out a single heater rather than shutting down the entire process. It’s a simple concept, but it’s one of the biggest reasons these heaters have become go-to components for so many OEMs.

The largest user of industrial duct heaters is the dehumidification market, particularly rooftop units like you see on big-box retail spaces. These massive systems are dedicated climate-control systems that manage humidity so that produce, clothing, and automotive goods don’t affect one another. The air remains clean through zoned dehumidification—and that requires reliable, consistent heat. TUTCO Farnam heaters are inside those rooftop systems all over the world, and many OEMs rely on their fast response and low-pressure-drop design to keep those units operating efficiently.

Beyond climate control, these heaters show up in drying systems, blow-off equipment, and applications where warm air simply performs better than ambient air. Whether it’s drying coatings, removing moisture from parts, or accelerating the evaporation of water during manufacturing, heated airflow always wins on speed and consistency. Industrial duct heaters also power the remediation industry. After a flood, fire, or water intrusion, restoration teams use portable climate-control units that push enormous volumes of warm, dry air into homes and buildings. Our heaters are built into many of these systems because they’re rugged, compact, easy to mount, and capable of cycling frequently without degrading performance.

Another application is environmental control units (ECUs) for military and industrial shelters. These soft-sided structures need stable internal temperatures regardless of the climate outside, and duct heaters help prevent air-conditioning coils from freezing while keeping the shelter comfortable. Similarly, environmental test chamber manufacturers rely on TUTCO Farnam heaters to create controlled temperature conditions, whether in small benchtop ovens or chambers large enough to pull in vehicles. These test chambers often serve industries transitioning from natural gas to electric heat, and the consistent responsiveness of an open-coil electric heater makes that shift feasible.

TUTCO Farnam uses nichrome resistance wire, 304 stainless steel rods, high-quality ceramic components, and robust termination materials. Watt densities can range up to 90 W/in², though most OEMs prefer lower densities for extended life. The correct watt density depends on temperature goals, airflow, and cycling expectations. From an electrical standpoint, these heaters can be built as single-phase or three-phase units, with voltages up to 600V and wattages ranging from under 1 kW to 75 kW per heater. Staged circuits are available for OEMs who want independent control over heat output or want to reduce amp load by splitting power across smaller-gauge wiring. TUTCO Farnam can also provide control solutions when required.

To learn what your application may require, get started with the Flow Rate Calculator and Build Your Own tools found on the TUTCO Farnam website.

TUTCO Farnam: Where Our Standard is Custom

by Jeff Elrod

Way back when I was a kid, I had a toy truck that was a semi-sized wrecker. I remember it well; it was one of my favorite toys. It was named the Orange Blossom Special. There was also a phrase on the side of the truck that said: “No Job Too Small.” As I started watching many big wreckers on the road while traveling to and from places, I noticed some of the big wreckers had the same phrase on them. I was intrigued by these words. I wondered why such a big rig had such words on it. I then did what most little boys do—I asked Dad, because Dad knows everything, and Dad had also worked in the automotive field for all his working life, even while in the Army. Dad explained that it meant that even though the rig was big in size—mighty, you might say—it was still willing to do the small jobs too. It would do whatever it needed to do to serve, you might say. This phrase on a kid’s toy taught me a lesson about serving others, no matter how insignificant we might view the task.

Way back when I was a kid, I had a toy truck that was a semi-sized wrecker. I remember it well; it was one of my favorite toys. It was named the Orange Blossom Special. There was also a phrase on the side of the truck that said: “No Job Too Small.” As I started watching many big wreckers on the road while traveling to and from places, I noticed some of the big wreckers had the same phrase on them. I was intrigued by these words. I wondered why such a big rig had such words on it. I then did what most little boys do—I asked Dad, because Dad knows everything, and Dad had also worked in the automotive field for all his working life, even while in the Army. Dad explained that it meant that even though the rig was big in size—mighty, you might say—it was still willing to do the small jobs too. It would do whatever it needed to do to serve, you might say. This phrase on a kid’s toy taught me a lesson about serving others, no matter how insignificant we might view the task.

At TUTCO Farnam Custom Products, we take this same attitude in the way we interact with our customers. We do not consider any job too small. We will look for a solution to your application no matter what the application is. Obviously, not everyone can do everything. We have a few scenarios that could happen to produce a heater for your application.

The first thing is to evaluate all our standard products and see if they are going to be able to be used in a manner to get the results needed. If the number of heaters needed is low and it is only going to be done once, this offers the best solution if possible. We can do a lot of configurations on these products to get something that will work in many applications. This option is generally the quickest and the most economical approach for many low-volume applications. This type of solution would include our Axial Fan Heaters, Crossflow Blower Heaters, Heat Torches, Cool Touch, Flow Torches, Pressure Torches, and our Industrial Duct Heater product lines..

The second option is that we may refer you to one of our sister companies that might have an off-the-shelf or standard product solution. Working within our sister companies, we can offer a solution that is better suited for your application and still comes from the TUTCO name that so many know and trust.

The last option would be a custom solution. This option is better suited for larger-volume applications because it will require design time, testing, and in many cases, production tooling. We have custom products used in a variety of industries including pollution abatement, life sciences and medical sectors, plastics, packaging, drying, and dehumidification, just to name a few.

We love coming up with a solution for our customer’s challenges and are willing to get out of our standards and “Think Outside the Box.”

FEATURE APPLICATION

Standby Generators and Wet Stacking

TUTCO Offers a Smarter More Reliable Solution

Diesel standby generators are essential for critical infrastructure, but they’re vulnerable to a performance-robbing issue called wet stacking. When a generator runs under light load for long periods, unburned fuel can accumulate in the exhaust system. The results are costly: reduced performance, increased maintenance, premature component failure, and shortened engine life.

Diesel standby generators are essential for critical infrastructure, but they’re vulnerable to a performance-robbing issue called wet stacking. When a generator runs under light load for long periods, unburned fuel can accumulate in the exhaust system. The results are costly: reduced performance, increased maintenance, premature component failure, and shortened engine life.

One generator manufacturer recently turned to TUTCO Heating Solutions Group after experiencing repeated failures with the ceramic heating elements they were using to dissipate excess load. Their existing design—an exposed-coil ceramic resistor—worked in ideal conditions, but in real-world job sites filled with dust, dirt, and airborne debris, the elements simply didn’t hold up.

TUTCO engineers stepped in with two modern, robust alternatives designed specifically to withstand the demanding environments where diesel generators operate.

Upgrading Reliability: Two TUTCO Heater Solutions

Finned Strip Heater – Direct Drop-In Upgrade

The first recommendation was a Finned Strip Heater engineered as a direct replacement for the outdated ceramic resistor. Unlike exposed coils, these heaters feature protected elements that dramatically improve durability and extend service life. Stainless steel fins increase surface area and enhance heat transfer, delivering steady, controlled load dissipation whether operating in forced-air or natural-convection conditions.

Originally used in duct heaters, shrink tunnels, and drying ovens, finned strip heaters have recently emerged as a powerful solution for generator enclosures—offering greater reliability, cleaner operation, and significantly longer lifespan compared to ceramic coil resistors.

Silicone Rubber Heaters on Angle Brackets – Modular and Scalable

For applications requiring a more flexible and customizable approach, the manufacturer also evaluated UL-listed Silicone Rubber Heaters mounted on angle brackets. This modular design allows wattage to be scaled quickly to meet specific load requirements.

These industrial-grade heaters use etched-foil elements to maintain uniform surface temperatures and exceptional heat distribution. Their durable silicone construction resists vibration, shock, moisture, and mechanical wear—making them ideal for rugged generator cabinets. Whether the system is running continuously or sitting idle for long stretches, these heaters deliver dependable, repeatable performance cycle after cycle.

Built for Harsh Environments

Diesel generator applications demand heaters that can withstand vibration, debris, weather exposure, and unpredictable operating cycles. TUTCO heaters are engineered for this reality. With more than 2,000 unique heating element designs and multiple manufacturing locations for redundant production, we offer both reliability and supply-chain confidence. Our team works closely with customers on an application-by-application basis to ensure the heater design aligns with the exact load requirements and environmental challenges of each generator model.

Let’s Talk About Your Wet Stacking Challenge

Wet stacking isn’t just a nuisance—it’s a problem that affects efficiency, emissions, and long-term equipment health. Using electric heaters as a controllable load is a proven way to prevent unburned fuel buildup and ensure generators run cleaner and more reliably.

Whether you’re developing new systems or upgrading legacy equipment, TUTCO can help you integrate a smarter thermal solution that protects your investment and improves generator performance.

FEATURE VIDEO

Our People at TUTCO SureHeat

At TUTCO SureHeat, our work goes far beyond building high-temperature air heaters. Every day, our team in Exeter brings together engineering precision, manufacturing expertise, and an uncompromising focus on safety and quality. The products we create are trusted in demanding applications around the world—from aerospace and advanced manufacturing to energy, research, and environmental systems. But behind every heater that leaves our facility is a team of dedicated people—problem solvers, craftsmen, innovators, and collaborators—committed to doing things the right way. We take pride in our attention to detail, our responsiveness to customers, and our drive to continually raise the bar in performance and reliability. This video highlights the individuals and the teamwork that power TUTCO SureHeat. It’s a look at the pride we take in our work, the culture we’re building together, and the excellence that defines everything we do.