Think About the Heater Sooner Rather Than Later

At TUTCO, we work with customers every day to develop process heating solutions that integrate seamlessly into their systems. All to often, one of the most common things we find ourselves saying is, “Wow, I really wish you had brought us in sooner.”

Why? Because early collaboration leads to smarter, more efficient, and more cost-effective heating solutions. When we’re involved from the beginning, we can tailor the heater to your system’s exact needs—maximizing performance, reducing costs, and ensuring a perfect fit.

Why Timing Matters

Many times, by the time a client reaches out to us, they’ve already designed most of their system, leaving little room for flexibility. At that point, we often find ourselves working within tight constraints—sometimes quite literally backed into a corner—where design choices are limited. This can lead to compromises in heater placement, airflow efficiency, or overall system performance.

Had we been involved earlier, we could have provided a solution that not only fits better but performs more effectively. Perhaps the heater could have been designed to take up a bit more width but less length, or vice versa. Maybe a slight change in system layout could have allowed for better heat distribution. These small adjustments can make a big difference in efficiency, cost, and ease of integration.

The Importance of Airflow

When designing a heating solution, airflow is a crucial consideration—often more critical than many customers realize. Air, much like water in a stream, follows the path of least resistance and prefers to move in a straight line. When forced to navigate sharp corners or bottlenecks, it can build up or become unevenly distributed, reducing efficiency.

Our goal is to maximize heat transfer by ensuring that the air comes into direct contact with as much of the heater’s coil as possible. The more efficiently air flows through the system, the better the heating performance. By involving us early in the design process, we can help you avoid common airflow pitfalls and create a more effective heating solution from the start.

Smarter, Simpler Solutions

Beyond airflow, early involvement also allows us to explore other choices that help enhance efficiency, such as:

- Optimized Heater Shape & Placement – We can adjust dimensions to fit your system without sacrificing efficiency.

- Complete Thermal Solutions – We may be able to design plug-and-play units that simply drop into place, saving time and effort.

- Cost Savings – A custom-tailored solution early in development is often more cost-effective than making last-minute adjustments or retrofits.

Let's Talk Early

If you’re developing a new system that requires process heating, let’s start the conversation sooner rather than later. By working together from the beginning, we can design a heating solution that is more efficient, more cost-effective, and better suited to your needs.

Different Types of Leadwire Insulating Material

by Ian Renwick

There are many different types of leadwire insulating materials that we can provide with our heaters. There really isn’t any type of material we can’t use as an insulating material on the leadwire of a heater, unless it can’t fit. That’s really the only physically limiting factor. Why select from different insulating materials? The two main factors are temperature rating and water resistance. Other factors are cost and form-factor.

At TUTCO, we used mica insulated leads as our default leadwire. It has a very good temperature rating of 450°C (842°F) and is comprised of stranded nickel conductors so it’s flexible and has a good ampacity. We also carry Teflon insulated leads as a moisture resistant alternative, which is great for applications where water is present, but it doesn’t have such a high temperature rating of only 250°C (482° F). Unfortunately, plastic and rubber insulations (or anything made from an organic compound) that can resist water have a temperature rating that can’t exceed about 500°F. For things hotter than that you’ll have to go to non-organic insulations which are typically not water resistant. You can have one or the other, but not both.

That’s where leadwire protection comes in. We can provide mica insulated leads with heat-shrink sleeving over them, or convoluted armor, both which will keep water away. If you’re looking for an inexpensive insulation you might want to try PVC. It has a rating of only 105°C (220°F) but it can keep water away. You need to be careful in how these leads are connected to heaters. They can’t be too close to a hot part of a heater, such as if they’re internally connected inside a cartridge heater, because the insulation will get damaged from excessive heat.

SJO Cord is a popular option when you want all the conductors (power leads and groudwire [if called for]) to be held in the same outer jacket that provides good protection from water. It’s also handy if you want to attach a plug to the end of the leads. The insulating material is neoprene rubber (polychloroprene) and has a temperature rating a little lower than PVC of 90°C / 194°F so similar precautions must be taken.

If used on a cartridge heater you’ll want an unheated length of at least an inch or two to keep the heat away from the rubber insulation. SJO Cord can’t be used on all our heaters because the conductors are held together in a single outer jacket, so the connecting points can’t be too far apart, like with an Ultima Strip Heater, for example.

At the other end of the temperature scale there are some conductors that are insulated with a high temperature material able to withstand 550°C (1020°F) for those applications where the leads need to run through very hot spaces. The insulation is a proprietary mica/glass composite, is not the least bit water resistant and the leadwires are quite thick in diameter, sometimes 50% thicker than our default mica insulated wires. That makes them unsuitable for some heater where they simply won’t fit. These leads with a very high temperature rating are also quite expensive. We do have a few sizes of the wire in stock, but not all of them. In the case of this exotic leadwire, don’t assume we can build you something without a conversation first.

In some of these cases where we don’t normally carry a specific leadwire in-house, customers have provided the leadwire to us to use in their heaters. We have one particular customer that doesn’t like the texture of one of our leadwires, so they provide their own when they place an order. Another customer wants the most flexible leadwires imaginable, so they provide us a17 ga rubber insulated wire with 210 strands(!) when placing an order.

Another point to consider is the seal called for on the heater. If you’re going to want a moisture resistant heater built with Teflon leads (for example) don’t forget that you’ll probably need to go with an epoxy or RTV seal in the heater. Our default seal is cement, which is porous, so using it in a moist environment isn’t a great idea, especially when you’ve gone to the effort of specifying moisture resistant leadwires.

Here’s a table that summarizes the details above:

| Insulation Type | Temperature Rating (ºC) | Temperature Rating (ºF) | Moisture Resistance | Ease of Use (For Manufacturing) | Cost | Availability |

| Mica | 450 | 842 | Poor | Easy | Medium | Common |

| Teflon | 250 | 482 | Good | Easy | Medium | Common |

| PVC | 105 | 221 | Good | Easy | Low | Common |

| SJO Cord | 90 | 194 | Good | Medium | Medium/High | Common |

| Mica/Glass | 550 | 1022 | Poor | Difficult | High | Special |

At TUTCO, we can offer you a variety of leadwire insulating materials, many of which we have in stock and can build into heater right away. If you have special requirements, please contact us to discuss and we’ll see how we can accommodate your needs.

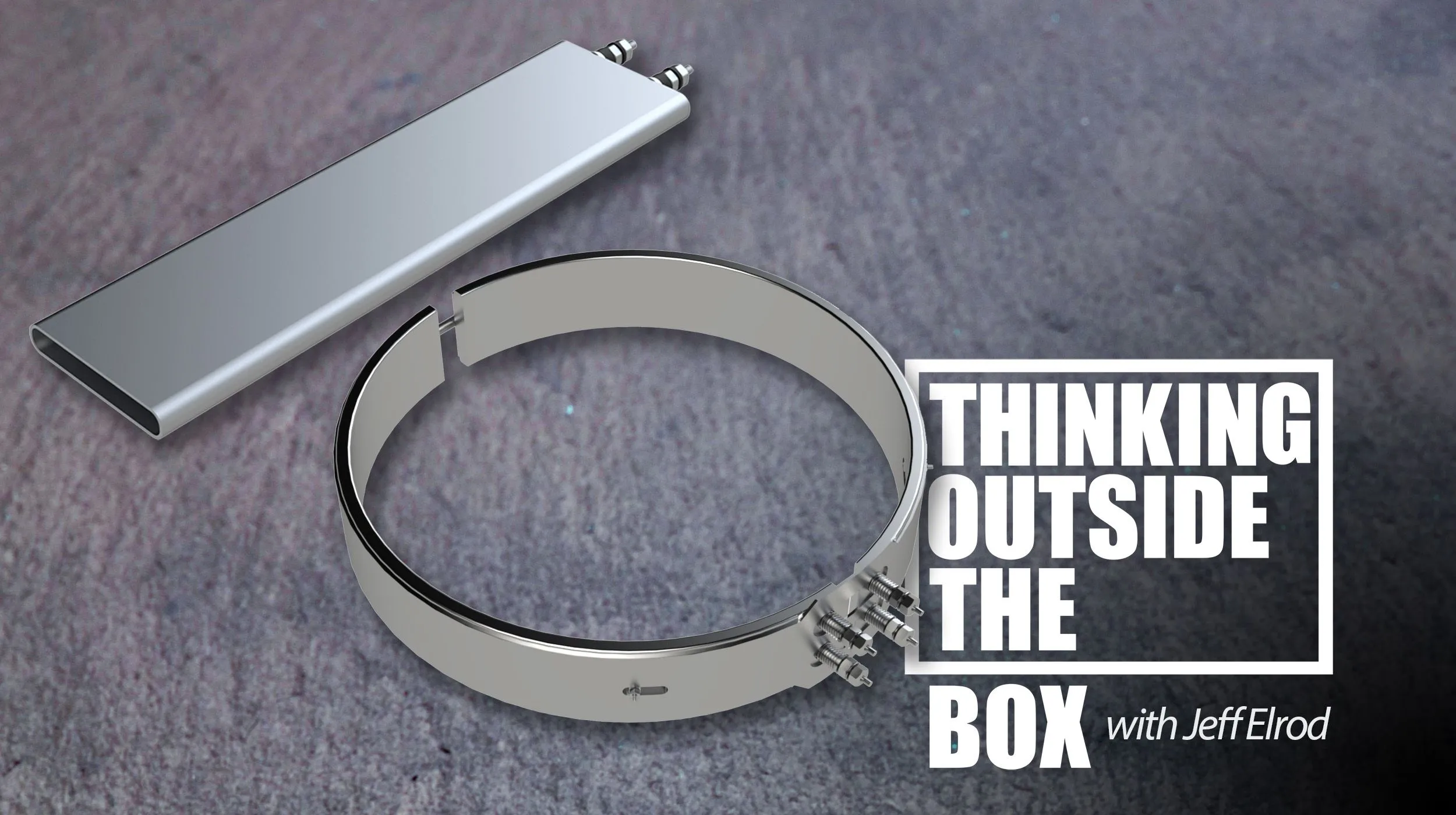

The Ultimate Heat

The Ultima Series of band and strip heaters produced by TUTCO Conductive deliver a robust selection of band and strip heater options to meet the need of a variety of applications. These heaters will operate up to 1200°F (648°C) and will withstand most corrosive environments and harsh installations. Ultima heaters start with a stainless-steel tubular heating element that is inserted into a 3/8” thick x 1 1/2” wide stainless-steel sheath which is then filled with MgO to allow for quick high heat transfer. They are available with a watt density of 40 to 45 Watts/In² of heating surface. These heaters are used in many process heating applications from aerospace, custom plastic molding dies and molds to custom made solutions, like a heater used to keep a cast iron pot of soup at specified serving temperature.

The Ultima Series of band and strip heaters produced by TUTCO Conductive deliver a robust selection of band and strip heater options to meet the need of a variety of applications. These heaters will operate up to 1200°F (648°C) and will withstand most corrosive environments and harsh installations. Ultima heaters start with a stainless-steel tubular heating element that is inserted into a 3/8” thick x 1 1/2” wide stainless-steel sheath which is then filled with MgO to allow for quick high heat transfer. They are available with a watt density of 40 to 45 Watts/In² of heating surface. These heaters are used in many process heating applications from aerospace, custom plastic molding dies and molds to custom made solutions, like a heater used to keep a cast iron pot of soup at specified serving temperature.

This heater style is available in a wide variety of electrical terminations. We can do basic screw stud terminals with or without a stainless-steel terminal box, high temp leads with lengths to match your system requirements with stainless steel braid, stainless steel armor and fiberglass sleeving protection available. We can also offer a stainless-steel terminal box with a German Plug installed into the terminal box. We can also offer a variety of other plugs, just let us know what plug you require, and we will evaluate and should be able to offer it to you.

The TUTCO Ultima Band heaters can be built with Inside diameters from 5” to 30” and larger diameters can be evaluated and sometimes built. These heaters come standard with 2-piece construction but some designs can be built is 3, 4, or possibly more segments. The clamping hardware is heavy duty 1/4-20 SHCS w/ clamp bars with spring bolt and Belleville washer clamping optional.

The TUTCO Strip heaters are available from 5 to 50” in length but longer lengths may be possible but need to be evaluated by the factory. These heaters will look very similar to a standard ceramic strip heater but they are much more robust with optional mounting tabs, brackets and even fins for rugged air heating applications.

If you need a non- standard Ultima heater, please consult the factory and we will be happy to evaluate and see if we can offer you something to meet your needs as we are happy to do custom configurations. Please contact us; we would love to help you with all your conductive heater needs whether it be the Ultima product line or another one of our other conductive products.

FEATURE INDUSTRY

Silicone Rubber Heaters

TUTCO Farnam has designed hundreds of heaters for surgical, laboratory, and patient comfort applications around the world.

![]() In healthcare, every detail matters—especially when it comes to keeping patients safe, comfortable, and supported during treatment. That’s why medical equipment manufacturers around the world trust TUTCO Farnam to deliver custom heating solutions that perform with precision and reliability. From the operating room to recovery, TUTCO Farnam’s heaters play a behind-the-scenes but essential role. In fact, more than 70% of patient warming blankets in use today are powered by a custom-designed TUTCO Farnam heater. These systems help keep patients warm during surgery and recovery, reducing stress on the body and improving outcomes. But it doesn’t stop there.

In healthcare, every detail matters—especially when it comes to keeping patients safe, comfortable, and supported during treatment. That’s why medical equipment manufacturers around the world trust TUTCO Farnam to deliver custom heating solutions that perform with precision and reliability. From the operating room to recovery, TUTCO Farnam’s heaters play a behind-the-scenes but essential role. In fact, more than 70% of patient warming blankets in use today are powered by a custom-designed TUTCO Farnam heater. These systems help keep patients warm during surgery and recovery, reducing stress on the body and improving outcomes. But it doesn’t stop there.

TUTCO Farnam’s heaters are found in:

- Surgical tools and devices that keep fluids and equipment at just the right temperature

- Ventilators and oxygen systems that warm air for patient comfort

- Warming cabinets that heat blankets and fluids before use

- CPAP machines, dialysis equipment, and humidifiers that rely on steady, safe heat

- Medical imaging devices like CT scanners, where controlled temperatures help produce clearer, more accurate results

With decades of experience and a reputation for precision, TUTCO Farnam has become a trusted name in medical device innovation. Their heating solutions are built to perform reliably, day after day, in some of the most critical environments imaginable. Whether it’s keeping patients warm during surgery or helping deliver life-saving treatments, TUTCO Farnam is proud to support the people and technologies driving better healthcare around the world.

FEATURE VIDEO

Thermal Process Controllers

TUTCO Farnam’s Thermal Process Controllers are convenient plug- and-play products that offer a complete thermal solution for application where you need to heat up shop or compressed air from 200 to 500º F. In this month’s video, learn how these fully integrated systems take the guesswork out of heating applications by combining all essential components into one convenient, wall-mountable steel enclosure. Each system includes a high-performance heater, a state-of-the-art digital controller, a flow switch, and a solid-state relay—delivering precise temperature control and reliability. Designed for applications requiring moderate wattage with 120V or 240V power, these heaters can handle airflows up to 25 SCFM and pressures up to 120 PSIG, achieving temperatures up to 260°C (500°F) depending on airflow.