Inside the World of Conductive Heat

At its most fundamental level, conductive heating is based on resistive, or Joule, heating. When electrical current passes through a resistive material, that resistance converts electrical energy into heat. In an industrial heater, this resistive material is typically a carefully selected metal alloy formed into a wire or ribbon. As current flows, the element heats up, and that heat is transferred outward into the heater’s sheath or ceramic structure, and then directly into the metal part or material that needs to be heated. Unlike convective or radiant systems, conductive heaters do not waste energy heating surrounding air or large volumes unnecessarily—the heat goes straight into the workpiece.

At its most fundamental level, conductive heating is based on resistive, or Joule, heating. When electrical current passes through a resistive material, that resistance converts electrical energy into heat. In an industrial heater, this resistive material is typically a carefully selected metal alloy formed into a wire or ribbon. As current flows, the element heats up, and that heat is transferred outward into the heater’s sheath or ceramic structure, and then directly into the metal part or material that needs to be heated. Unlike convective or radiant systems, conductive heaters do not waste energy heating surrounding air or large volumes unnecessarily—the heat goes straight into the workpiece.

This direct heat transfer is what gives conductive heaters their defining advantages. Cartridge heaters, for example, are designed to slide into precision-drilled holes in molds, platens, or manifolds. A tight mechanical fit allows heat to move efficiently from the heater sheath into the surrounding metal, producing fast heat-up times and highly stable temperatures. Ceramic band heaters take a different approach, wrapping around barrels or cylindrical components and transferring heat through a combination of conduction and controlled radiation. While the form factors differ, the operating principle remains the same: electrical energy is converted into localized, controllable heat exactly where it is required.

Where conductive heating becomes more complex—and more powerful—is in the engineering details. Watt density, internal element temperature, heater-to-part fit, insulation quality, and control strategy all play a role in performance and service life. A heater designed to deliver high power in a compact space can dramatically improve cycle times, but if it is pushed beyond its thermal limits or paired with poor temperature control, its lifespan can be shortened. Likewise, a heater that fits too loosely may be easy to install, but it sacrifices heat transfer efficiency and consistency. These trade-offs are why conductive heating should never be treated as a purely off-the-shelf component in demanding OEM applications.

Temperature control is another critical part of the system. Conductive heaters respond quickly, which makes them ideal for precise control—but only when paired with appropriate sensors and controllers. Proper thermocouple or RTD placement, along with solid-state or SCR-based power control, reduces thermal cycling and stress on the heating element. The result is smoother operation, better process stability, and longer heater life. In contrast, basic on/off control can introduce temperature swings that accelerate fatigue and reduce reliability over time.

For OEM engineers, the appeal of conductive heating lies in this balance of simplicity and precision. The underlying physics are straightforward, yet the performance potential is extremely high when the heater is engineered to match the application. Conductive heaters are compact, adaptable, and capable of delivering fast, localized heat with minimal energy loss—qualities that are increasingly important as manufacturers seek greater efficiency and tighter process control. At TUTCO Conductive, we approach conductive heating as an engineered solution rather than a commodity part. Material selection, dimensional tolerances, watt density limits, termination options, and control recommendations are all considered as part of the overall system. By aligning the heater design with the machine geometry and process requirements, conductive heating becomes not just a source of heat, but a reliable, long-term contributor to equipment performance. Conductive heating may appear deceptively simple: pass current through a resistor and it heats up. But the real value comes from executing that concept correctly. With the right materials, tight tolerances, and smart control strategies, conductive heaters deliver the efficiency, precision, and durability that modern industrial equipment demands.

ENGINEERING INSIGHTS

TUTCO Farnam Answers the Call on Control Panel Issue

by Jeremy Golden, TUTCO Farnam Engineer

![Jeremy Golden]() One thing I always tell our customers is this: call us early if you’re having trouble with your process heaters or control systems. You would be surprised how many headaches—and how much downtime—can be avoided with a quick conversation. Too often, customers try to troubleshoot alone for weeks or months, when all they really needed was a nudge in the right direction.

One thing I always tell our customers is this: call us early if you’re having trouble with your process heaters or control systems. You would be surprised how many headaches—and how much downtime—can be avoided with a quick conversation. Too often, customers try to troubleshoot alone for weeks or months, when all they really needed was a nudge in the right direction.

A perfect example of this happened recently.

A customer reached out after struggling with a control panel issue for months. Their system was an older design—built before 2022, back when the manufacturing of our control panels was still outsourced. They described their system as “wonky,” constantly powering on and off, and they mentioned that they were seeing temperature overshoot. None of this sounded normal, so I asked them to email over some details and then hopped on a video call to take a closer look.

Within minutes, the problem was obvious.

Inside every TUTCO panel is a high-limit control—a safety device that lets you define a temperature above which the system should not operate. This high-limit setting is designed to shut the system down only when something is truly wrong, preventing damage and unsafe conditions.

But in this case, the high-limit temperature was set too close to the customer’s desired process temperature. We typically recommend keeping these setpoints 50 to 100 degrees apart, depending on the application. Their process temperature was set at about 125°F, while the high-limit was set at 150°F—far too close. Small, normal fluctuations in process temperature were enough to trip the high-limit safety, causing the system to shut down repeatedly.

In other words, the safety mechanism was being used as a primary control—something it was never intended to do.

Once we explained the issue and helped them increase the high-limit setting, the problem immediately disappeared. What had been an ongoing frustration for months was resolved in under 15 minutes.

Situations like this tell us something important: when issues show up unexpectedly, something in the customer’s process usually changed.

Everything might have been working fine originally, but a slight change in airflow, load, operator behavior, or equipment condition can cause the system to behave differently over time. That’s why talking to us early can save a tremendous amount of wasted effort.

FEATURE APPLICATION

TUTCO Meets the Needs of Plastic Industry

Reliable Heat at Every Stage of Plastics Processing

From raw material preparation to final forming and finishing, heat is essential at every stage of plastics manufacturing. Processes such as injection molding, extrusion, blow molding, plastic welding, recycling, and deflashing all rely on accurate, consistent temperature control. Across these applications, the TUTCO Heating Solutions Group provide electric heating solutions designed specifically for the realities of plastics production.

Plastics operations include demanding conditions, with tight temperature tolerances and frequent thermal cycling. TUTCO heaters are engineered to perform reliably in these environments, delivering steady, controllable heat that supports consistent processing and high-quality parts. Rather than relying on off-the-shelf solutions, the TUTCO family works closely with equipment manufacturers and processors to design heaters that match the application, the equipment, and the process requirements.

Conductive heaters—including band, cartridge, strip, tubular, and also flexible heaters from TUTCO Farnam—are widely used on injection molding barrels and nozzles, extrusion equipment, platens, and forming tools. These heaters provide fast response and uniform heat transfer, helping maintain stable melt temperatures, reduce scrap, and improve cycle time consistency. In plastic welding, binding, and forming applications, precise heat control supports strong, repeatable joints without overheating surrounding materials.

Moisture control is another critical factor in plastics processing. Many resins must be thoroughly dried before molding or extrusion to prevent defects. TUTCO SureHeat and Farnam process air heaters are commonly used in hopper dryers, conveying systems, and moisture removal equipment, where their rapid response and precise control help maintain target air temperatures and airflow while minimizing energy waste. These same heaters also play an important role in plastic recycling and reprocessing systems, supporting consistent heating and material handling.

Across all of these applications, durability and integration matter. TUTCO heaters are designed around real-world operating conditions, including voltage, watt density, temperature limits, mounting requirements, and control strategies. This application-focused approach simplifies integration into OEM equipment, reduces downtime, and supports long-term reliability. With manufacturing in the United States and Asia, TUTCO supports plastics manufacturers worldwide with consistent designs, scalable production, and dependable lead times.

As plastics manufacturers continue to push for greater efficiency, improved product quality, and more sustainable processes, dependable electric heat remains a critical foundation. With a broad heater portfolio and decades of application experience, TUTCO, TUTCO Farnam, and TUTCO SureHeat provide the precision, reliability, and engineering support plastics operations need to keep production running smoothly.

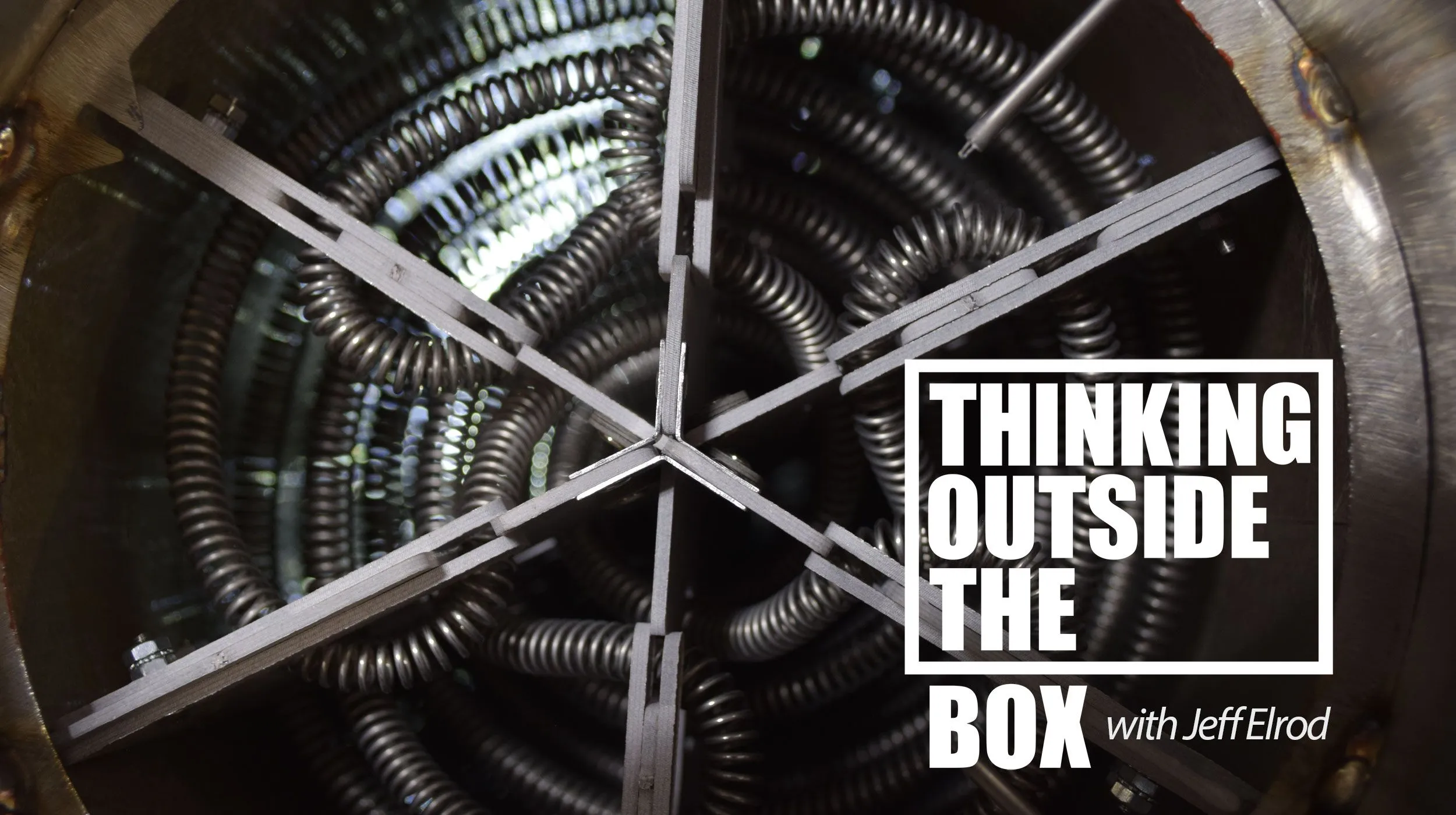

THINKING OUTSIDE THE BOX

You Got Me Under Pressure: The Pressure Torch & The Pressure Torch-Extreme!

by Jeff Elrod

As I sit trying to meet my publishing deadline on a Saturday night, yes, it’s been one of those weeks. I am watching the snow that, according to the forecast earlier this week, should be about 1 foot of a 2-foot total snowfall in Tennessee, but is just dusting. Now it is turning into freezing rain and accumulating ice, so not what was first forecast. I share this because we have been watching the weather closely, as this impending natural disaster has been staged for much of the USA. During this, I saw there was an exploding tree warning in upstate Michigan (yes, it’s real, Google it). While the trees are not technically exploding, when you have such a drastic change, like with a winter storm of this magnitude, it freezes the sap and other moisture inside the trees so quickly that the expansion builds internal pressure until the tree cracks or splits, causing a loud pop or bang, sounding like an explosion, sometimes even causing the trees to fall. Basically, the trees could not handle the pressure applied. Pressure is not always a bad thing, as it might seem; diamonds also come from pressure.

As I sit trying to meet my publishing deadline on a Saturday night, yes, it’s been one of those weeks. I am watching the snow that, according to the forecast earlier this week, should be about 1 foot of a 2-foot total snowfall in Tennessee, but is just dusting. Now it is turning into freezing rain and accumulating ice, so not what was first forecast. I share this because we have been watching the weather closely, as this impending natural disaster has been staged for much of the USA. During this, I saw there was an exploding tree warning in upstate Michigan (yes, it’s real, Google it). While the trees are not technically exploding, when you have such a drastic change, like with a winter storm of this magnitude, it freezes the sap and other moisture inside the trees so quickly that the expansion builds internal pressure until the tree cracks or splits, causing a loud pop or bang, sounding like an explosion, sometimes even causing the trees to fall. Basically, the trees could not handle the pressure applied. Pressure is not always a bad thing, as it might seem; diamonds also come from pressure.

Sometimes you have a need to heat pressurized air for some sort of process. For years, the Farnam Custom Products Heat Torches, Cool Touches, and even the Flow Torch 200—basically all our forced air heaters 2” or smaller—have been able to be used in systems up to 120 PSI with minimal leakage. Our larger 4”, 6”, and 8” models have only been able to be used up to 3 PSI with minimal leakage. So, a few years ago our engineering team developed the Pressure Torch product line. It is very similar to the Flow Torch line but is installed in a pressure vessel that can handle 150 PSI for those higher-pressure applications. This offering is available in 4” (PT400), 6” (PT600), and 8” (PT800) sizes. The wattage and voltage offerings would be the same as the equivalent Flow Torch heater. The only option for the connections is the 150 lb. flange fittings, and all heaters will come standard with two Type K thermocouples. Here is a link to the web page for this product: https://farnam-custom.com/pressure-torch-family.

These heaters are used in many manufacturing process applications, but we have also seen many of them used in research and development projects in lab settings. After this, we started seeing requests for the need for higher pressures, so while it has not been published on our website yet, we now have our Pressure Torch Extreme product family that will work up to 300 PSI (if interested in the PTX, please contact the factory). Also, many times we pair the Pressure Torch with either a standard UL508A heat control panel or with a custom UL508A control panel solution. We want to make Farnam your one-stop shop for system requirements for this type of product. Basically, make sure we get you in the proper product for the pressure your heat system is seeing so you do not wind up with “exploding trees.” Remember, we are always here to help you “Think Outside the Box” to get you the solution that will work for you.

These heaters are used in many manufacturing process applications, but we have also seen many of them used in research and development projects in lab settings. After this, we started seeing requests for the need for higher pressures, so while it has not been published on our website yet, we now have our Pressure Torch Extreme product family that will work up to 300 PSI (if interested in the PTX, please contact the factory). Also, many times we pair the Pressure Torch with either a standard UL508A heat control panel or with a custom UL508A control panel solution. We want to make Farnam your one-stop shop for system requirements for this type of product. Basically, make sure we get you in the proper product for the pressure your heat system is seeing so you do not wind up with “exploding trees.” Remember, we are always here to help you “Think Outside the Box” to get you the solution that will work for you.

FEATURE VIDEO

Specialty Flanged Inline Heaters (SFI)

This month’s feature video provides an in-depth look at TUTCO SureHeat’s Specialty Flanged Inline (SFI) Heaters, presented by Senior Application Engineer Rob Broadley. These electric heaters are designed for specialized applications that demand high pressures, extremely high temperatures, and the ability to heat large volumes of air or other process gases. The video explores the broad performance range of SureHeat’s SFI products—from low-pressure systems to designs operating at thousands of PSI, and from heaters rated in just a few kilowatts to large-scale, multi-megawatt installations. With axial designs capable of reaching temperatures up to 1100°C and compatibility with air, inert gases, and flammable gases in their inert state, these heaters are supporting advanced applications in aerospace MRO, hypersonic wind tunnels, decarbonization initiatives, carbon capture technologies, and most recently a large-scale direct reduction of iron project. TUTCO SureHeat SFI heaters can scale from compact, single-element designs to massive systems measuring up to eight feet in diameter, delivering unmatched flexibility for the most demanding heating challenges.

One thing I always tell our customers is this:

One thing I always tell our customers is this: