Control Panel Communication Protocols

In today’s industrial environments, control panels can do a lot more than be an onf/off switch—they easily regulate, systematically initiate, and seamlessly integrate to communicate with a wide range of your system components where automation is desirable. At TUTCO Farnam, communication protocols can be engineered into every panel, ensuring reliable data exchange across diverse systems and networks.

From controlling the heaters that TUTCO Farnam produces ensuring optimal performance in complex process heating applications to factory-floor automation. TUTCO Farnam’s custom control panels are designed to meet customer’s needs. Some of the most widely used industrial protocols, including EtherNet/IP, PROFINET, Modbus (RTU and TCP), and BACnet are just some examples of what we can offer.

Whether the control system is Allen-Bradley-based—where EtherNet/IP is native—or a Siemens platform running PROFINET, TUTCO Farnam panels can be configured to integrate with any platform. Each panel is engineered with the end-user’s application in mind, allowing for fast, reliable communication between controllers, sensors, and any other needs you may have.

Modbus, one of the most common protocols in industrial automation, is also a key part of TUTCO Farnam’s offerings. With the ability to support industry standards of both simple wired RTU (Remove Terminal Unit) or networked based TCP (Transmission Control Protocol) Modbus communications, our panels can serve a broad range of legacy and modern systems alike. BACnet support extends the panel’s capabilities into the building automation sector, where HVAC and environmental systems also require precise, responsive control.

TUTCO Farnam supports a full range of communication mediums based on application needs and environmental constraints. Local area network connections are incorporated into our standard panel offering, while optional wireless integration enables remote monitoring, diagnostics, and support from virtually any location.

TUTCO Farnam enables process, manufacturing, and controls engineers to implement reliable control regardless of what the panel is controlling or the communication protocol. The company’s ability to support both standard and custom protocol configurations ensures that each panel is a precise fit for the customer’s control needs.

Hypot Testing of Electric Heating Elements

by Ian Renwick

Ensuring the safety and reliability of electric heating elements is critical, and one essential test used to verify electrical insulation integrity is a hypot test. A hypot failure during this test is a serious issue that can indicate compromised insulation and potentially dangerous equipment. In this article, we’ll break down what a hypot failure is, what happens when it occurs and why it's dangerous.

What Is a Hypot Test?

A hypot test (short for high potential test) is an electrical safety test used to check the dielectric strength (electrical insulating strength) of insulation in electrical devices. Though you may get burned by touching a live electric heater, you should certainly never get electrocuted. That’s why we perform that test. The test ensures that the metal sheath of the heater is electrically separated from the circuit of the heater. It involves applying a high voltage—well above the heater’s normal operating voltage—between the conductive parts (like the heater’s leadwire or screw terminal) and the outer conductive (metal) parts (like the outer sheath of the heater), making sure that they’re electrically isolated from each other.

The purpose is to ensure that the insulation can withstand high voltages without breaking down or leaking too much current, which could lead to short circuits or electric shock during normal operation. Be aware that there is always a small amount of leakage current passing through, around or over insulation, but it is often low enough to be undetectable and not dangerous.

Why Test at Such a High Voltage?

Insulation has a dielectric rating, usually presented in Volts/Inch or Volts/mm. That rating is often a room temperature rating. As temperatures increase the dielectric strength of insulators decreases and there might be an electrical breakdown in an electric heater. We very often test at 1000V over the expected applied voltage (sometimes higher) in order to make sure the insulation can provide the protection it needs to at high temperatures.

What Is a Hypot Failure?

A hypot failure occurs when the insulation of a heating element cannot withstand the applied test voltage and allows current to leak through. This leakage current is detected by the test equipment, and if it exceeds a predefined limit, the test is failed. That predefined limit is typically 3.0 mA (or 3 thousandths of an amp). Sometimes it’s lower when the customer calls for it. It’s never higher than 3.0 mA.

Common Causes of Hypot Failures:

- If there is moisture inside the heater, that will lead to a hypot failure. In this instance don’t think of moisture as droplets of water (though it could be) but as moisture in the air. Dank air can cause a hypot test to fail.

- Manufacturing defects, such as voids or cracks in the insulation, be it mica, MgO, ceramic or some other insulator.

- Contamination with conductive materials like metal shavings or a stray wire strand.

- Damaged or deteriorated insulation due to overheating, aging, or corrosion. This is not found in newly manufactured heaters, but something that’s been in use for a while and has suffered deterioration from being very hot.

Why Is Hypot Failure Dangerous?

Hypot failures highlight potential electrical safety hazards. If a heating element with poor insulation is installed in a live system:

Shock Risk: Live voltage could transfer to the outer machinery, creating a shock hazard for users or anyone coming in contact with the live machinery

Fire Risk: Arcing or overheating from insulation breakdown can lead to electrical fires.

Equipment Damage: Poor insulation may cause short circuits that damage control boards or connected components.

System Downtime: Unexpected failures in the field lead to costly repairs and downtime.

In safety-critical industries (think of aerospace or medical devices), such failures can be catastrophic. Those industries always have the strictest test requirements, often including a very low leakage current allowance for the hypot test.

How Bad is an Electric Shock?

A 1 mA shock is perceived as a faint tingle.

At 5 mA, the shock is definitely felt as a shock and can be disturbing, though there is no lasting pain. Some involuntary movement of the limbs might occur. 6-30 mA is where the shock is painful, and control of the muscles is lost. There is where you reach the stage of not being able to let go of something due to involuntary muscular contractions.

50-150 mA is when there's no letting go, and death is certainly possible.

1-4.5 amps results in nerve damage, uneven heart pumping and probable death.

10 amps results in certain death due to cardiac arrest.

So yes, it’s pretty important to make sure you don’t get electrocuted, ever, and that list shows you the importance of hypot testing. It’s not the voltage that gets you, it’s the current!

Next time you see a lightning bolt you can think of it as a hypot failure of the air between the clouds and the ground. Lightning bolts very often carry 100 thousand amps (100 kA) at 100 thousand volts (100 kV). I guess it’s pretty hard to stop that from going where it wants to!

A hypot failure in electric heating elements is more than a failed test—it's a critical safety indicator. It reveals weak spots in insulation that could endanger users, damage equipment, or cause costly system failures. Through thoughtful design and rigorous testing we work hard to prevent hypot failures and ensure reliable, safe performance of our heating elements, both initially and throughout their life.

Understanding and respecting the importance of the hypot test is essential for anyone working with or around electric heating elements.

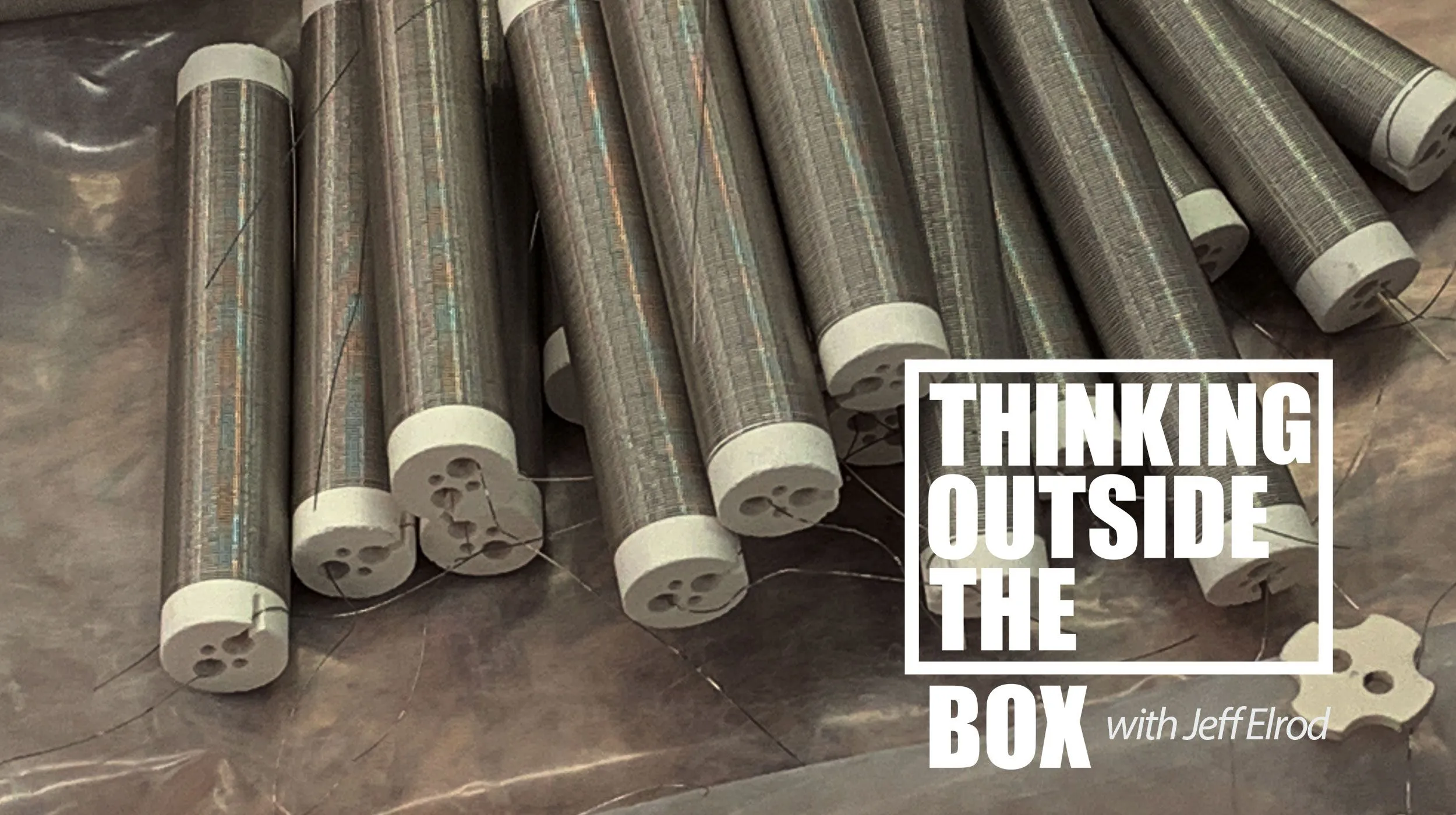

TUTCO Conductive: Offering Conductive and Then Some

by Jeff Elrod

The Tutco Conductive Group is known for its conductive cartridge, strip, and band heaters. We offer both Hi-Temp and standard cartridge heaters in a variety of configurations and ratings. We also offer four different types of band heaters and four different types of strip heaters. These conductive heaters are used in a variety of industries including, but not limited to, a multitude of plastics applications, sealing and packaging applications, food service, 3D printing, textile, agriculture, aerospace, and thermoforming applications. We have heaters in almost every conductive application that is in industry today.

The Tutco Conductive Group is known for its conductive cartridge, strip, and band heaters. We offer both Hi-Temp and standard cartridge heaters in a variety of configurations and ratings. We also offer four different types of band heaters and four different types of strip heaters. These conductive heaters are used in a variety of industries including, but not limited to, a multitude of plastics applications, sealing and packaging applications, food service, 3D printing, textile, agriculture, aerospace, and thermoforming applications. We have heaters in almost every conductive application that is in industry today.

The catch is that some of the heaters built by the Conductive Group can be used in non-conductive applications. Sometimes the cartridge heaters are used in air heating applications. They can be used in many forced air applications, and we offer the 3/8” diameter cartridge heaters with fins that allow for better heat transfer to air. Take the fins along with options like terminal plates and bulkhead fittings, and it gives a nice heater option for many different applications.

We also offer finned heater options on our Ceramic and Ultima strip heaters. These heaters are used in a variety of applications, and with the 1 ½” width of these strip heaters, they allow for a great deal of heat transfer into the air with the fins on convective applications. One application is using finned Ultima heaters to heat agriculture transport trailers where the area has to be washed down, and the application requires a rugged design.

Strip heaters can be used in convective applications without fins also. They have been used in a variety of applications including control panel heaters, comfort heat for small areas, ovens, and lab applications. We have one application in public transportation where a simple HT Mica Strip Heater was used under the seats on passenger train cars to knock the chill off the air at the floor to keep passengers’ feet warm.

Another use that is still conductive, but is heating liquids instead of solids, can be done with our flat bar heaters and our tubular heaters. This can be done with food service applications such as frying and boiling, lab applications where liquids and gases need to be heated, and other similar applications in industrial processes.

So whatever the application, give us a shot, because between all of our divisions, we can generally offer you a solution for your problem by “Thinking Outside the Box.”

FEATURE INDUSTRY

Transportation: Maritime Applications

Navigating the Harsh Seas with Reliable Thermal Solutions

The sea is harsh environment—especially for the equipment that keeps vessels moving safely and efficiently. Whether sailing through Arctic cold or Caribbean heat, marine systems must withstand some of the harshest conditions on Earth. Salt-laden air, humidity, condensation, vibration, and freezing temperatures are constant threats to reliability. That’s where TUTCO Farnam steps in, delivering heating solutions engineered to keep marine operations running smoothly, no matter the environment.

Condensation inside instrumentation panels is a constant battle at sea. Fogged displays and corroded contacts don’t just reduce performance—they can shut down operations. Our Axial Fan Heaters are purpose-built for these environments, maintaining stable internal temperatures that prevent moisture buildup. Compact and efficient, they’re trusted inside navigation consoles, sealed enclosures, and communications panels to protect sensitive electronics and ensure reliability in the toughest marine conditions.

When bridge windows fog or freeze, safety is on the line. Our Crossflow Blower Heaters create a curtain of warm air that keeps glass surfaces clear, even in cold or humid weather. Quiet, compact, and designed to withstand salt spray and vibration, they give captains and crews the visibility they need to navigate confidently in any climate.

Engines and generators can be stubborn in freezing conditions. Cold batteries lose charge, and oil thickens until it won’t flow properly—leading to frustrating, sometimes dangerous startup failures. Our Silicone Rubber Heaters prevent these issues by keeping batteries warm and oil at the right viscosity. With waterproof construction, adhesive backing, and custom-fit options, they’re a rugged solution for tight engine bays and challenging marine environments.

Every TUTCO Farnam heater is engineered with the realities of marine operation in mind: corrosion-resistant materials, flexible mounting options, and designs that withstand constant motion, vibration, and salt exposure. From protecting sensitive electronics to ensuring cold-weather readiness, our heaters are trusted by shipbuilders, integrators, and operators worldwide.

FEATURE VIDEO

Our Team at TUTCO Farnam

This month’s feature video shines a spotlight on what truly sets TUTCO Farnam apart—our people. From the engineers who design cutting-edge heating solutions, to the sales team who partners closely with customers, to the skilled line workers who build with precision every day, each shares a unique perspective on their role and their commitment to excellence. Together, they reveal how collaboration, innovation, and a shared dedication to quality drive our ability to deliver the best heating solutions in the industry. Beyond products and processes, it’s the culture at TUTCO—across all our global locations—that makes us strong. This video is a celebration of the passion, expertise, and teamwork that fuel TUTCO Farnam and ensure our customers can count on us, no matter the challenge.