TUTCO CONDUCTIVE

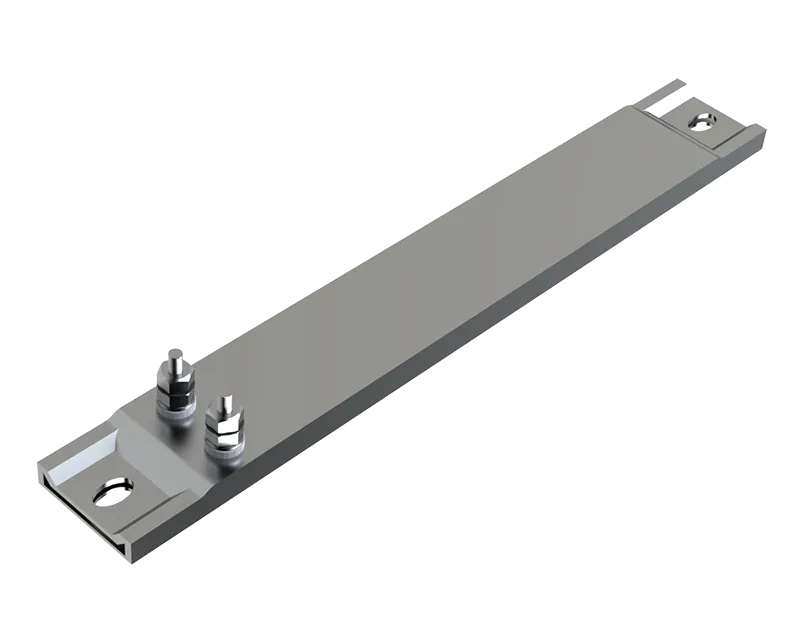

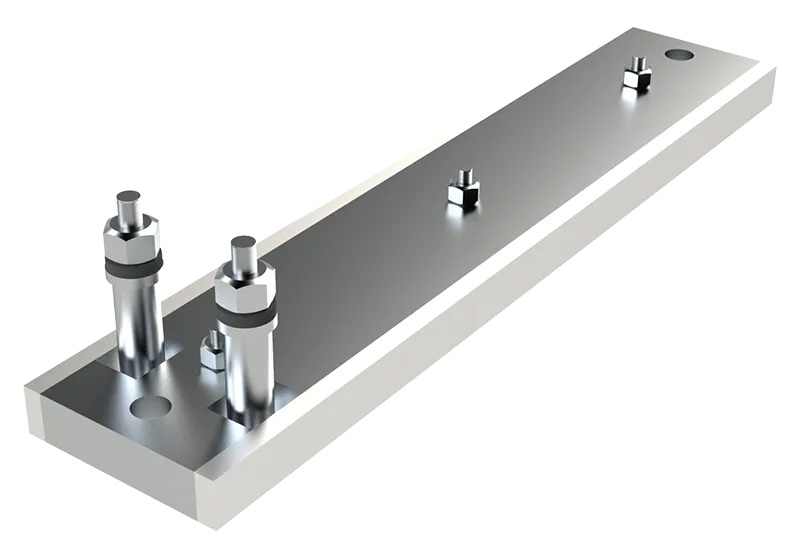

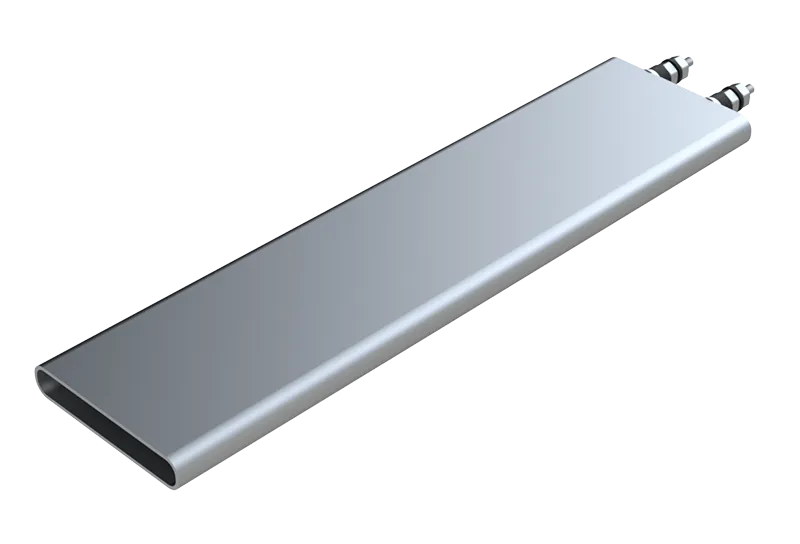

Permaheat Strip Heaters

TUTCO’s aluminum Permaheat Strip Heater is built to handle the applications with tough environments with reliable performance and durability. Its design features a tubular heating element, which ensures efficient heat transfer while resisting contamination—making it a dependable choice for heavy-duty applications. The heater’s aluminum body is precisely extruded, allowing the tubular elements to fit perfectly in place for optimal performance. The aluminum construction not only adapts well to various surfaces but also acts as a great heat transfer material. This means it heats up quickly and maintains an even temperature throughout, eliminating hotspots and ensuring consistent results every time. Whether you’re using it in industrial processes, manufacturing equipment, or other demanding environments, the Permaheat Strip Heater is designed to deliver a reliable, long-lasting performance.

FEATURES AND BENEFITS

- Excellent heat distribution

- Rapid heat up

- Rugged construction

- Long life due to tubular construction

- Large selection of lengths, sizes and terminations

- Various termination options

- Vibration and contamination resistant

- Consult factory for other custom options

| Specifications | |

| Maximum Operating Temperature | 600°F (315ºC) |

| Max Watts per square inch | 35 watt/in²' |

| Durability | Excellent |

APPLICATIONS

- Platen Heaters

- Compression Mold Heaters

- Plastic Pellet Dryers

- Packaging and Sealing Bars

- Form Fill Packaging Machines

- Food Grade Sealing/Wrapping

- Food Service Warming

- Ink Heaters

- Textile Processing

- Chemical Processing

- Laboratory Warmers

- Laminating Applications

- Scientific Testing Equipment

- Glass Processing

- Holding Tanks

- Drum & Barrel Heating

- Incubators/Medical

- Space haters for public transportation

- Road construction equipment (asphalt)

Frequently Asked Questions

Most failures aren’t caused by the heater itself—they usually result from installation or operational issues. Common problems include poor surface contact, dirty or uneven surfaces, damage to lead wires or terminals during handling, and exceeding the heater’s specified watt density or temperature. Taking the time to ensure the surface is clean and flat, leads are properly routed, and mounting hardware is secure will help the heater last longer and deliver consistent, reliable performance.

Yes, that’s one of its strengths. Because the heating elements are embedded in the aluminum extrusion, they’re better protected from dust, oil, or other contaminants than exposed coil designs. While no heater is completely impervious to buildup, this design makes it easier to clean and maintain, and it keeps the heater in tight contact with the surface for consistent heat transfer.

The Permaheat Strip Heater stands out because of its precision-extruded aluminum body. This design presses the tubular heating elements directly into the aluminum, which not only delivers fast, even heat but also helps the heater maintain contact with slightly irregular or imperfect surfaces. That means it can handle vibration, dust, and other challenging conditions without losing performance. In short, it’s built to be reliable even when the environment isn’t perfect.