TUTCO CONDUCTIVE

Permaheat Band Heaters

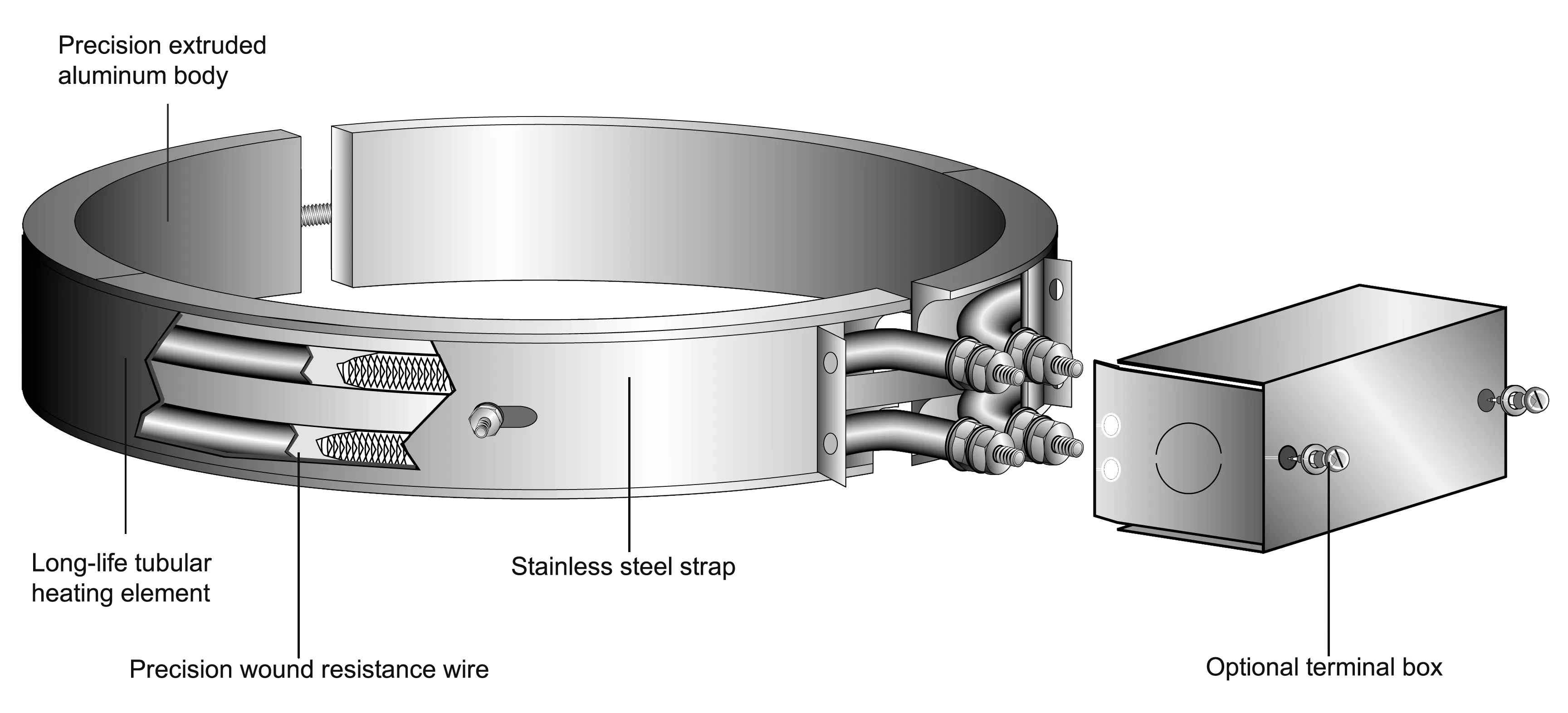

TUTCO’s durable aluminum Permaheat Band heaters use a tubular heating element to deliver excellent heat transfer and resistance to contamination. The tubular elements are placed in a precisely extruded aluminum base. This aluminum base is normally sectioned to ensure a positive contact with the object being heated. The aluminum body also serves as an excellent transfer medium for rapid heat-up while providing a uniform temperature throughout the entire band.

FEATURES AND BENEFITS

- Resistant to contamination

- Durable tubular heating element

- Aluminum extrusion allows for even heat distribution

- Precision wound resistance wire

- Between 20 gauge stainless steel strap for added clamping strength

- Standard high strength 1/4 - 20 clamping hardware

- Straight threaded terminals or normally supplied on all Permaheat heaters

| Specifications | |

| Maximum Operating Temperature | 600°F (316ºC) |

| Holes | Consult Factory |

| Cutouts | Consult Factory |

| Durability | Excellent |

APPLICATIONS

- Extruders & Extrusion Die Heaters

- Plastic Injection Molding

- Injection Molding Nozzle Heaters

- Blown Film Processes

- Blow Molding Machines

- Food Processing

- Candy Extruders

- Food Service Warming

- Holding Tanks

- Drum & Barrel Heating

- Chemical Processing

- Scientific Testing Equipment

- 3D Printers

- Medical Process Heater

In addition, Permaheat Bands can be modified to meet the demands of virtually any special application. Our engineers can utilize a variety of alternative features and options to customize the heater to your specific needs.

Frequently Asked Questions

Uneven heating is usually caused by poor contact between the heater and the component or contamination on the surface. Checking the clamping hardware, cleaning the component, and ensuring the heater sections are aligned properly typically resolves most issues.

Permaheat Band Heaters are versatile and can often be retrofitted to existing cylindrical components, provided the inside diameter, width, and clamping method match the existing equipment. In many cases, replacement heaters can be custom-sized to fit older machines, reducing downtime and the need for major modifications.

The Permaheat Band Heater’s design enhances both durability and resistance to contamination. Its tubular heating element is embedded within the aluminum body, which protects the element from exposure to dust, debris, and other contaminants common in industrial environments. The aluminum extrusion also ensures consistent thermal conductivity while providing mechanical protection. In addition, the heavy-gauge stainless steel strap and high-strength ¼-20 clamping hardware maintain tight contact with the heated component, preventing gaps that could reduce heat transfer or cause uneven performance. Together, these features make the Permaheat Band Heater highly reliable for demanding industrial applications.

The Permaheat Band Heater uses a tubular heating element embedded in a precisely extruded aluminum body. The aluminum extrusion serves dual roles: it provides excellent thermal conductivity (rapid heat-up and transfer) and ensures uniform temperature across the band surface. The heater is strapped around the component using a heavy-gauge stainless steel strap and high-strength ¼-20 clamping hardware to maintain tight contact and uniform conduction.