TUTCO CONDUCTIVE

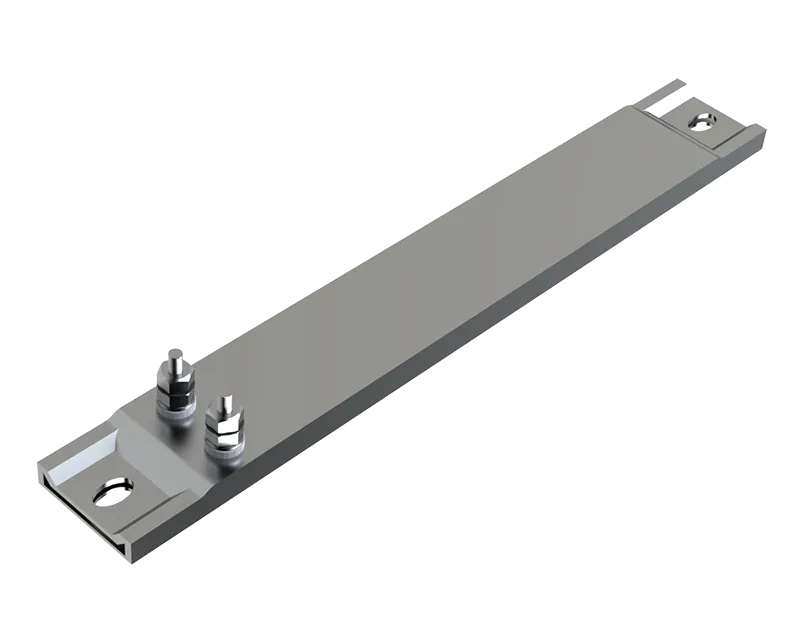

HT Mica Strip Heaters

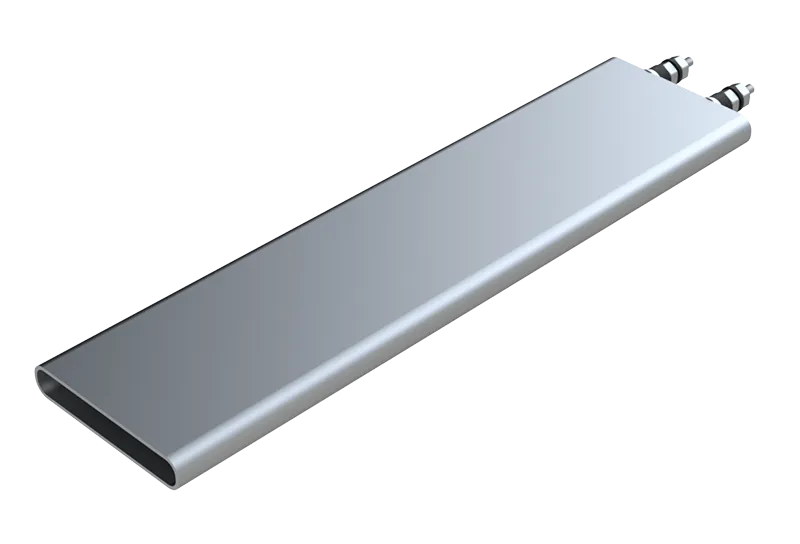

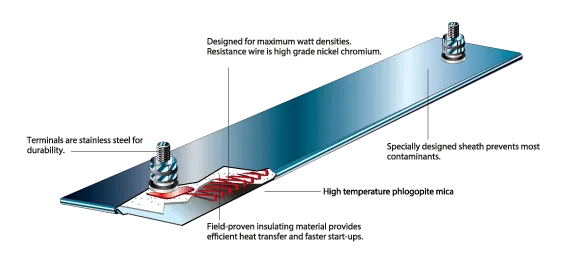

TUTCO HT Mica Strip heaters are a cost-effective and reliable way to provide uniform heat over a flat surface. Best suited for low to moderate temperatures, our HT Mica Strip heaters offer a wide variety shapes, sizes and termination styles. HT Mica Strips feature thin construction and quality high-temperature Phlogopite Mica insulation for effective heat transfer and excellent dielectric qualities. Some expedites available. Consult factory.

FEATURES AND BENEFITS

- Computer calculated design

- Quality Phlogopite mica electrical for higher temperatures than heaters with muscovite mica

- Ribbon resistor offers broad surface contact for extended life

- Welded terminal attachments to resistors

- Heat resistant sheath material

- Variety of screw terminal and lead termination available

- Mounting holes, slots, and cutouts available

- Consult factory for other custom options

| Specifications | |

| Maximum Operating Temperature | 900°F (482ºC) |

| Holes | Yes |

| Cutouts | Yes |

| Max Watts per square inch | 45 watt/in²' |

| Durability | Good |

APPLICATIONS

- Platen Heaters

- Compression Mold Heaters

- Plastic Pellet Dryers

- Packaging and Sealing Bars

- Form Fill Packaging Machines

- Food Grade Sealing/Wrapping

- Food Service Warming

- Ink Heaters

- Textile Processing

- Chemical Processing

- Laboratory Warmers

- Laminating Applications

- Scientific Testing Equipment

- Tin and Flux Melting

- Glass Processing

- Holding Tanks

- Drum & Barrel Heating

- Incubators/Medical

EITHER END

ONE END FROM THICKNESS

ONE END ON TOP

Leads can be arranged at either end or at the same end, exiting from the top, the thickness at the end(s) of the heater or the width at the side of the heater. All HT Mica heaters come standard with mica insulated leads. Standard lead length is 10″. Other lengths available upon request.

Engineering Note

Improperly chosen lead arrangements are a major cause of application problems. Use special care in selection of leads where physical abuse and high temperatures are likely.

EITHER END

SAME END ALONG LENGTH

SAME END ALONG WIDTH

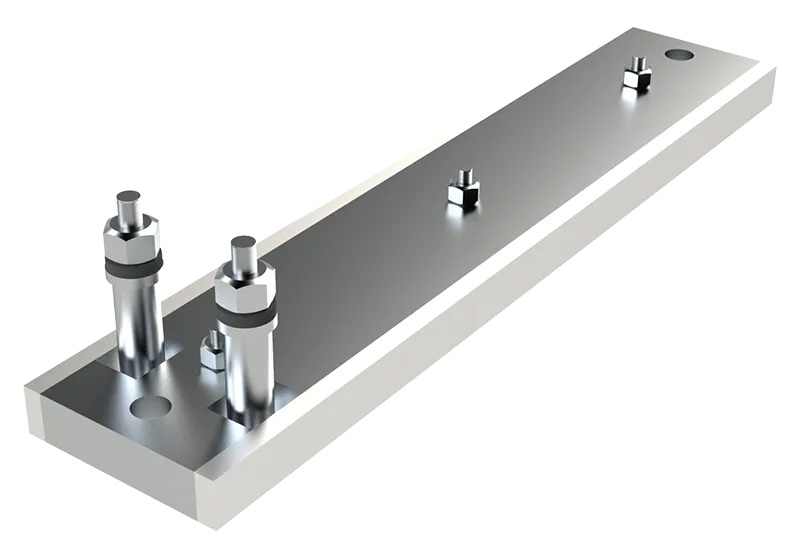

Simple to wire stainless steel screw terminals are available arranged at each end, on the same side arranged along the length, or on the same side arranged along the width. All screw terminations are good up to 20A. Optional ceramic covers are available.

PLAIN LEADS

Our high temperature mica insulated leadwire with nickel standard conductors is suitable for continuous service up to 842°F (450°C).

SLEEVING

Fiberglass silicone rubber coated sleeving class C1, 392°F (200°C) service. Provides extra insulation where wire is exposed to heat, molten plastics or abrasion. Rated for 1500 volts at 428°F (220°C), except 5/16" size which has no voltage rating.

STAINLESS STEEL BRAID

Stainless steel over braid is most commonly specified in applications where leads may be subjected to abrasion due to movement of the application. Lead wires may be rubbing together or passing over sharp objects.

STAINLESS STEEL ARMOR

Used over leads in areas where more protection is necessary. Selected for similar applications as the stainless steel braid, in addition to applications where non-fluid contamination may come in contact with the leads. This lead protection is not as flexible as the braid. Stainless steel square lock construction.

CONVOLUTED ARMOR

This is a seamless product and can be attached to the heater so that fluids do not contaminate the leads. This system of lead protection is generally associated with the Sealed Band construction. Not recommended where leads are flexed in the application.

COPPER ELBOW

Simple straight abrasion-resistant stainless steel armor or moisture-resistant armor is attached to a 90° copper elbow to accommodate applications where lead access is only possible from one side and armor exit direction is a concern. When ordering without a swivel option, specify direction of 90° copper elbow.

PIPE COUPLING/EXTENSION TUBE

These pipe couplings, welded to the heater sheath, provide a method of fastening conduit or armor to the heater which can be disconnected from the heater as required. Standard stainless steel.

STANDARD TERMINAL BOX

Designed for protection safety, snap-off cover leaves terminals easily accessible.

European Power Plug Options

EUROPEAN PLUG

EUROPEAN PLG W/ BRACKET

EUROPEAN PLUG W/ BOX

The European Power Plug is illustrated in the most common position. There are occasions for special boxes where the plug may be positioned on the top surface of the box.

Other Plug Options

QUICK DISCONNECT SOCKET

2 pole, 25 amp, 250V, 600°F (315°C) service. Ideal for power connection to heaters. Durable cast aluminum body on female side. Both sides have ceramic insert insulators. Ground connection via contact fingers.

SPECIALTY PLUGS

Customer to specify type, part number and amperage required.

CUTOUTS

HOLES

Special units manufactured to meet your unusual requirements are available. Typical examples of special variations would include unusual sizes, non-rectangular shapes, holes, slots, cutouts, wattages, voltages, terminations and mounting systems. Consult TUTCO for alternate sheath material and higher temperature applications, cutouts, unusual holes, special curvatures to fit on pipes or cylinders.

Frequently Asked Questions

While HT Mica Strip Heaters are rated for a maximum of around 45 W/in², the safest approach is to consider your specific setup. Factors like surface flatness, how tightly the heater will be clamped, and any air gaps between the heater and the surface can affect heat transfer. In many cases, reducing watt density to about 20 W/in² helps prevent hot spots and prolongs the heater’s life. Paying attention to these details ensures your heater performs reliably without risk of overheating.

Many problems with mica strip heaters come from simple installation issues. Mounting the heater on a surface that isn’t clean or flat can create air gaps, leading to uneven heating or hot spots. Over-tightening or under-tightening the clamps can warp the heater, and rigidly fixing it at both ends without allowing for thermal expansion can cause stress that eventually damages the element. Additionally, leaving the heater exposed to oils, debris, or molten materials can degrade the insulation over time. Taking a few extra minutes to prep the surface and install the heater carefully pays off in longer, trouble-free operation.

Yes! One of the advantages of mica strip heaters is their flexibility. They can be customized to fit specific flat surfaces, including cutouts, holes, slots, or unique lead termination styles. Providing a drawing or diagram of your surface, including where leads should exit or any special shapes, helps the manufacturer design a heater that fits perfectly and delivers consistent heat across the entire area. This makes them ideal for platens, sealing bars, or any custom flat-surface application.

Mica strip heaters are excellent for flat surfaces and moderate temperatures, up to about 900 °F, but they do have limitations. If you need higher temperatures, curved or irregular surfaces, or extremely rugged conditions, a ceramic or tubular heater might be a better choice. Mica strips also require good surface contact and careful watt density management—pushing too much power through a poorly mounted heater can lead to hot spots and shorten its lifespan. Understanding these limits helps ensure you choose the right heater for your application and get reliable performance over the long term.