TUTCO CONDUCTIVE

Hi-Temp Cartridge Heaters

TUTCO Hi-Temp Cartridge Heaters are a reliable, high-performance heating solution for a wide range of applications, including plastics, chemical processing, packaging and industrial processes. Our Hi-Temp Cartridge heaters are high watt density heaters that provide excellent heat transfer efficiency and up to 100 Watts/in² with high operating temperatures. The Hi-Temp Cartridge is made to withstand a sheath temperature of up to 1200°F (649°C) continuously and 1400°F (760°C) intermittently. Its swaged construction allows for minimal internal air gaps, providing superior heat transfer and resistance to impact and vibration. Dual voltage and three phase options are available on selected diameters.

FEATURES AND BENEFITS

- High watt density rugged construction

- Efficient dissipation of heat

- Many voltage variations and power options

- Wide-range of diameters

- Many termination styles – see below

- CSA and UL recognized (where applicable)

- High quality Nickel-Chromium connections provide consistent junctions and termination

- Use in distributed wattage systems

| Specifications | |

| Maximum Watt Density | 100 Watts/sq. in |

| Maximum Sheath Temperature | 1200°F continuous, 1400°F intermittent |

| Sheath | Incoloy 800 |

| Wattage Tolerance | +5%/– 10%, based on NEMA standards |

| Resistance Tolerance | +10%/–5% 3.3% lower at room temperature |

| Standard Voltages | 120V, 240V. Others available upon request |

APPLICATIONS

- Compression Molding

- Blown Film Processes

- Blow Molding Machines

- Plastic Pellet Drying

- Platen Heaters

- Packaging and Sealing Bars

- Form Fill Packaging Machines

- Textile Processing

- Chemical Processing

- Laboratory Warmers

- Bolt Heaters

- Laminating Applications

- Scientific Testing Equipment

- 3D Printers

- Plastic Pipe Cutting / Joining

- Glass Processing

- Food Grade Sealing/Wrapping

- Food Service Warming

- Refrigeration

- Automotive Applications

- Space Heaters for Public Transport

- Agriculture Transportation

- Holding Tanks

- Drum & Barrel Heating

- Battery Warmers

- Deicing Applications

- Defrost Heaters

- Cryogenic Applications

- RV Water Heaters

- Control Panel/Enclosure Heater

RESOURCES

Cartridges can be modified to meet the demands of special applications. Our engineers can utilize a variety of alternative features and options to customize the heater to your specific needs. Common customizations include:

- Internal Thermocouples

- Flanges, Top Rings, Tabs

- Brass or Stainless Steel Threaded Bushings

- Special Seals of Epoxy, RTV, Teflon

- Leadwire Protection, Stainless Steel Braid

- Leadwire Protection, Stainless Steel Armor

- Distributed Wattage

- No-Heat Sections

- Three Phase Construction

- Dual Voltage

- Zoned Heaters

- Square Cartridge Heaters

Learn more about customizing cartridge heaters in Ian Renwick’s white paper.

FLEXIBLE LEADS

Internally connected leads. For applications requiring maximum flexibility at lead exit. 10” (25.4 cm) leads standard, other lengths are available.

EXTERNALLY CONNECTED LEADS

Hi-Temp Cartridges are provided with approx. 1” (25.4 mm) sleeving over lead junction as standard. 10” (25.4 cm) leads standard, other lengths are available.

STRAIGHT LEADS WITH CLIP SUPPORT

Clip support helps to minimize lead breakage where leads exit heater. 10” (25.4 cm) leads standard, other lengths are available.

90° LEADS

Leads exit at 90° angle for applications where space is limited. 10” (25.4 cm) leads standard, other lengths are available. Order heater by overall length.

90° LEADS WITH CLIP

Clip support helps to minimize lead breakage where leads exit heater. 10” (25.4 cm) leads standard, other lengths are available.

STAINLESS STEEL BRAID

Stainless steel braid over lead wires. For applications requiring small radius bending and lead wire abrasion protection. 10" (25.4 cm) braid standard, other lengths are available.

STAINLESS STEEL ARMOR

Straight stainless steel armor cable protects leads from abrasion. Sizes include: 1/4", 5/16", 1/2", and 5/8". 10" (25.4 cm) standard, other lengths are available.

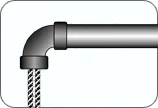

RIGHT ANGLE ELBOW

Right Angle Elbow Right angle copper elbow for applications requiring right angle lead exit. Moisture-resistant seal is optional. 10" (25.4 cm) leads standard, other lengths are available.

STRAIGHT STRAIN RELIEF SPRING

Straight strain relief spring minimizes bending strain on lead wires. Spring extends approximately 3" (76.2 mm) beyond end of sheath.

NPT BUSHING

Hex head N.P.T. bushing attached. Must specify insert length and bushing material. Sheath material types: stainless steel, cold rolled or galvanized. Bushing material types: brass or stainless steel. Octagonal box available.

HEX CENTER BUSHING

Hex head N.P.T. bushing attached. Must specify insert length and bushing material. Sheath material types: stainless steel, steel or brass. Bushing material types: brass and stainless steel. Octagonal or explosion-proof boxes can be adapted to both Standard and Hi-Temp Cartridge heaters.

ADAPTER

Must specify insert length and bushing material. Sheath material types: stainless steel, cold rolled or galvanized. Bushing material types: stainless steel.

ADAPTER WITH HEX HEAD

Must specify insert length. Bushing material is copper.

BOTTOM GROUNDED

For fast response, heater is positioned in a blind hole or where material flows past or encompasses the heater. The end disk is always welded in place. Machined flat up to 1/2″ (12.7 mm) dia.

BOTTOM UNGROUNDED

Where circumstances are such that an ungrounded thermocouple is required.

CENTER GROUNDED

Selected when a fast response is required. The thermocouple can be located in any position along the length of the heater. Standard location is midway along the length with approximately 1/4″ (6.4 mm) cold section on either side of the junction. Not available on 1/4” diameter heaters.

CENTER UNGROUNDED

The thermocouple is positioned internally and ungrounded to monitor the heater temperature. Generally used in research and development applications.

Thermocouple Availability

All heaters shown are Hi-Temp with type “J” thermocouple standard. Type “K” thermocouples are available. For standard Cartridge heaters thermocouples are available located at the bottom or center, ungrounded only.

ARMOR WITH PLUG

Armor cable with power plug attached. Must specify armor length and Hubbell ® power plug number. Moisture-resistant armor available. Other Plugs are available. Also available with Hex Head NPT bushing and armor.

BOLT HEATER

Bolt heaters are designed to heat drilled metal surfaces quickly while minimizing heat loss to surrounding areas. Each is designed to expand drilled bolts or studs while maintaining a uniform heat throughout its heated length. Typically, after a bolt is heated (expanded) the holding nut is tightened. The shrink tightness is obtained when the heater is removed and the bolt cools. This process is frequently used in the assembly and/or servicing of heavy duty equipment such as compressors, steam turbines, pressure vessels, etc.

Frequently Asked Questions

Standard cartridge heaters are designed for dry, enclosed applications. Exposure to moisture or liquids can damage the insulation or cause electrical shorts. If your process involves liquid contact, TUTCO offers sealed or specialized designs that can withstand those conditions safely.

Lead wires and terminations aren’t just an afterthought—they can make or break heater performance. Properly rated and protected leads prevent electrical shorts, wear, or failure from vibration or high temperatures. Options like braided stainless steel leads or strain-relief fittings help heaters survive tough industrial environments while maintaining reliable electrical connections.

Yes — as long as the heater’s sheath material and termination are appropriate for your environment. Stainless steel sheaths, for example, resist corrosion and contamination, making them suitable for food-processing equipment. For sensitive electronics, the heaters provide localized heating with minimal stray heat, but you should always consider insulation and safety controls to prevent accidental contact or overheating.

Cartridge heaters are ideal when you need precise, localized heat in a compact space. If you’re heating molds, dies, or small metal blocks—or any setup where you can insert a cylindrical heater—they provide efficient, uniform heat. They’re especially useful for applications requiring high temperatures in a small footprint, like plastics processing, packaging, or lab equipment.