Ceramic Strip Heaters for Plastics

Precision Heating for Demanding Applications

Ceramic strip heaters are essential in the plastics industry, offering high-temperature, uniform surface heating where reliability and durability are critical. Engineered for rugged environments and precise thermal control, ceramic strip heaters are widely used in plastics processing applications including injection and extrusion dies, compression and platen heater installations, molding and form-fill equipment, plastic pellet dryers, and plastic melter systems.

What Are Ceramic Strip Heaters?

Ceramic strip heaters consist of a nickel-chromium resistance wire embedded in a ceramic core and enclosed in a durable stainless-steel sheath. This construction allows them to deliver high watt densities and maintain uniform surface temperatures up to 1200°F (649°C). Their flat surface makes them ideal for mounting to platens, dies, and other contact surfaces requiring consistent heat distribution.

Contact customerservice@tutco.com if you have questions.

Why Choose Ceramic Strip Heaters for Plastics?

- Temperature Capacity: Up to 1200°F (649°C)

- Watt Density: High output for rapid response

- Custom Options: Length, voltage, terminal orientation, and mounting brackets Industrial

- Durability: Built for continuous use in harsh environments

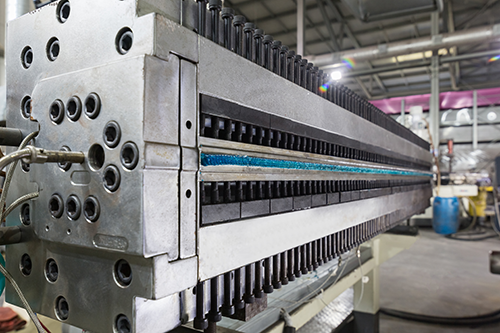

Injection and Extrusion Dies

In injection molding and extrusion operations, ceramic strip heaters are commonly used to heat die heads, manifolds, and flow channels. Consistent die temperatures are crucial to maintaining material flow and achieving optimal melt quality.

In injection molding and extrusion operations, ceramic strip heaters are commonly used to heat die heads, manifolds, and flow channels. Consistent die temperatures are crucial to maintaining material flow and achieving optimal melt quality.

Stable Heat Output: Ceramic strip heaters minimize temperature fluctuations, reducing scrap rates and enhancing product consistency.

Custom Mounting Options: Available in multiple lengths and terminal configurations, they can be easily integrated into existing die assemblies.

Corrosion-Resistant Construction: The stainless-steel sheath resists chemical exposure from polymers and cleaning agents.

Whether it's a blown film die or an extruder head, ceramic strip heaters deliver the thermal performance needed for high-throughput plastic production.

Compression and Platen Heater Installations

Compression molding and other platen-based systems require even heat across flat surfaces to mold thermoplastics and thermosets properly. Ceramic strip heaters are ideal for mounting directly to press platens or into slots for indirect heating.

Uniform Surface Heating: Their flat design ensures full surface contact, promoting even material curing and mold filling.

Durability Under Pressure: Built to withstand the mechanical stress of platen presses, these heaters operate reliably under compressive loads.

Fast Heat-Up Times: Ceramic heaters reduce downtime by achieving process temperatures quickly.

Used in thermoplastic composite molding, laminate curing, and high-pressure forming, ceramic strip heaters provide dependable heat when and where it matters most.

Molding and Form-Fill Equipment

Plastic form-fill-seal (FFS) systems and thermoforming machines rely on precise zone heating to shape and seal materials. Ceramic strip heaters provide excellent heat control in zones where air heaters or infrared elements may fall short.

Plastic form-fill-seal (FFS) systems and thermoforming machines rely on precise zone heating to shape and seal materials. Ceramic strip heaters provide excellent heat control in zones where air heaters or infrared elements may fall short.

Consistent Zone Control: Ceramic strip heaters deliver stable heating across sealing bars and forming zones, critical for packaging integrity.

Easy Maintenance: With simple mounting brackets and accessible terminals, heater replacement and maintenance are straightforward.

Long Service Life: With proper installation and control, ceramic strip heaters operate for years without failure.

For automated packaging lines and plastic forming systems, ceramic heaters improve product yield and reduce energy waste.

Plastic Pellet Dryers

Plastic resin drying systems depend on controlled heating to remove moisture from pellets before processing. Ceramic strip heaters are often mounted inside hopper dryers, tray dryers, and drying tunnels.

High Watt Density: Capable of achieving the temperature levels needed to drive off surface and absorbed moisture.

Non-Contaminating: The clean stainless-steel outer shell ensures no particles or off-gassing enter the material stream.

Compact Form Factor: Allows integration into tight spaces within drying bins and chambers.

Moisture-laden pellets can cause steam bubbles, poor mold filling, and structural defects. Ceramic strip heaters improve drying consistency and material integrity.

Plastic Melter Systems

From hot melt adhesive tanks to plastic extrusion preheaters, plastic melter systems require controlled heating zones to keep materials at flow-ready temperatures. Ceramic strip heaters are ideal for these applications due to their:

From hot melt adhesive tanks to plastic extrusion preheaters, plastic melter systems require controlled heating zones to keep materials at flow-ready temperatures. Ceramic strip heaters are ideal for these applications due to their:

Reliable Heat Control: Maintain constant melt temperatures with integrated thermocouples or external sensors.

Mounting Versatility: Attach easily to reservoirs, tanks, and feed zones.

Safe and Durable: Encased in metal and designed for continuous high-heat operation, ceramic heaters withstand demanding melt conditions.

Whether you're working with EVA, LDPE, or specialized thermoplastics, ceramic strip heaters keep melters flowing efficiently.

Request a Quote or Technical Consultation

Looking for a heating solution tailored to your plastics application? Our engineering team can help you specify the ideal ceramic strip heater configuration for your equipment. Whether it's OEM integration or MRO replacement, we deliver high-performance heaters built to last.