TUTCO CONDUCTIVE

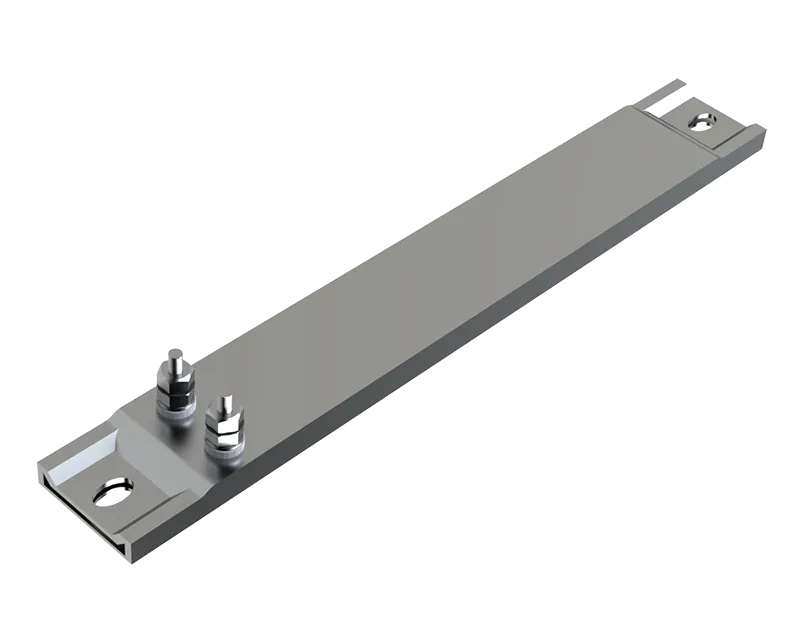

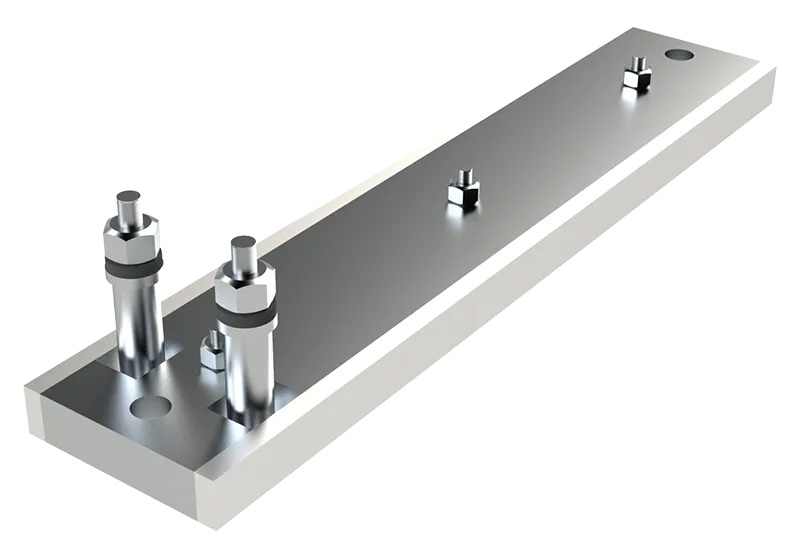

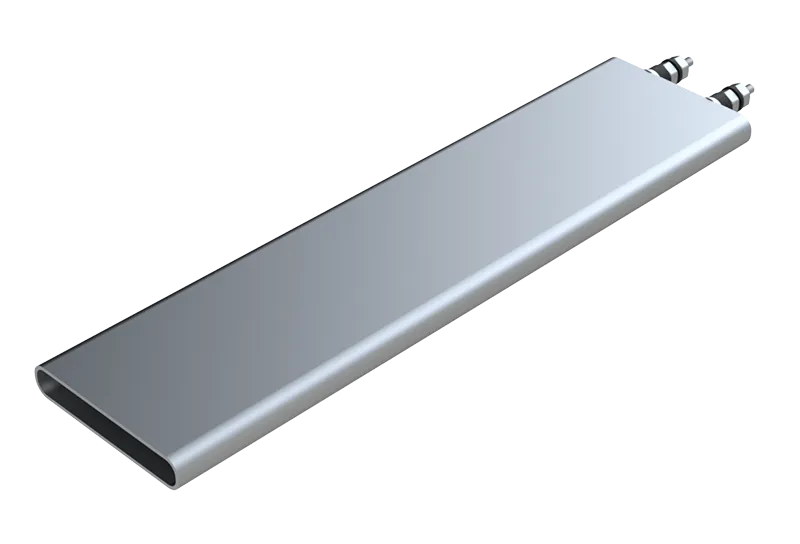

Ceramic Strip Heaters

TUTCO’s Ceramic Strip Heaters are engineered for reliable, high-efficiency performance across a broad range of industrial and medical heating applications. Built with a rugged 304 stainless steel sheath, each strip heater element is capable of withstanding high temperatures—typically limited to 40 to 45 watts per square inch, depending on the specific application.

Inside each industrial ceramic strip heater, a nickel-chrome wire coil is housed within a high-temperature ceramic core. Magnesium oxide (MgO) fills any air pockets, maximizing heat transfer. The terminals, made of stainless steel, are securely anchored to prevent twisting or failure during normal use. Water-resistant terminations and a variety of lead configurations—including fiberglass leads and stainless-steel braided options—are available to suit your environment. Click here for information about proper mounting of ceramic strip heaters.

Our Ceramic Strip heaters also known as Rod Heaters provide a dependable, versatile and efficient heat source for a wide range of applications, such as heating air, injection and extrusion dies, food tables and platens. Whenever possible, please provide a dimensional sketch of your requirements with your order.

Standard lead time: 10–15 business days. Expedited options available. Consult the factory for customizations.

FEATURES AND BENEFITS

- Fast heat-up and high thermal efficiency

- Long service life with low expansion materials

- Available in single- and 3-phase configurations

- Custom lengths, wattages, and mounting options

- Distributed wattage and channel strip heaters available

- Durable construction for demanding environments

| Specifications | |

| Maximum Operating Temperature | 700°F (371ºC) |

| Max Watts per square inch | 40 watt/in²' |

| Durability | Good |

Our ceramic resistance heaters are ideal for heating solid surfaces and air in a wide range of commercial and industrial environments.

APPLICATIONS

Injection and extrusion dies

Compression and Platen Heater Installations Molding and Form-Fill Equipment

Plastic Pellet Dryers

Plastic Melter Systems

Packaging and Heat Sealing Bars

Shrink Tunnels and Packaging Lines

Form Fill Packaging Machines

Heater Strip Element in Automation Lines

Food Grade Sealing/Wrapping

Food Service Warming and Platen Warming Tables

MEDICAL AND LABORATORY

Ink Heaters Textile Processing

Scientific Testing Equipment

PROCESSES

Ink Heaters

Textile Processing

Chemical Processing

Laboratory Warmers

Laminating Applications

Scientific Testing Equipment

Glass Process Stations

OTHER INDUSTRIAL APPLICATIONS

Holding Tanks

Drum & Barrel Heating

Incubators/Medical

Duct Heating & Space Heaters for Transportation

TEXTILE AND CHEMICAL PROCESSING

Chemical Processing

Laboratory Warmers

Laminating Applications

Scientific Testing Equipment

Glass Processing

Fiberglass Leads Simple leads designed for maximum heated length and to accommodate applications where leads can only be accessed from one end and height clearance is a concern. 10" (25.4 cm) leads standard, other lengths available. Stainless steel braided lead is optional. Mounting tab option is available only on end opposite lead end.

EITHER END

SAME END ALONG LENGTH

SAME END ALONG WIDTH

SAME END DIAGONAL

FROM THICKNESS

Simple to wire screw terminals are available arranged on either end, on one side either along the width, along the length or diagonally, or from one end from the thickness of the heater. Available with mounting tab option (Single tab available).

FINNED CERMAMIC STRIP HEATERS

Tutco has a complete line of finned strip heaters designed to provide excellent heat transfer to forced air or natural convection (like a cabinet or oven). Finned strip heaters are available in a full range of sizes, wattages and voltage ranges. Typical applications for finned strip heaters include duct heaters, space heaters, drying ovens and shrink tunnels. Stainless steel fins are standard. Fin Dimensions: 2" (50.8mm) wide x 1 3/8" (34.9mm) high.

Frequently Asked Questions

Even though TUTCO’s ceramic strip heaters come with sturdy stainless-steel terminals and water-resistant options, picking the right lead type for your environment is really important. Fiberglass, stainless braid, or armored leads each have their strengths depending on whether your setup involves moisture, vibration, or chemicals. Before installation, think about where the leads will run and make sure they’re not getting bent, pinched, or exposed to strain. A little planning here can prevent a lot of headaches down the road.

Mounting is where a lot of problems sneak in. The surface needs to be clean, flat, and free of oils or debris. Tight clamping helps, but it’s also a good idea to leave a little room for expansion because the heater will grow slightly when it heats up. Applying a thin layer of thermal paste or spray can really improve heat transfer. After the first heat-up, double-check the screws and alignment—sometimes things shift a tiny bit as it settles. Doing this little bit of extra work ensures the heater performs reliably.

Yes, even though these heaters are rugged, they’re not invincible. If your process involves harsh chemicals, extreme vibration, or very high watt densities, you’ll need to make sure the heater is specified correctly. Exceeding its limits can reduce its lifespan or cause failure. Think of the heater as part of a system—the environment it operates in, how it’s mounted, and how often it cycles all affect how well it performs over time.