Engineering Insights

3D Printing Technology Requires Specific Heaters And Sensors

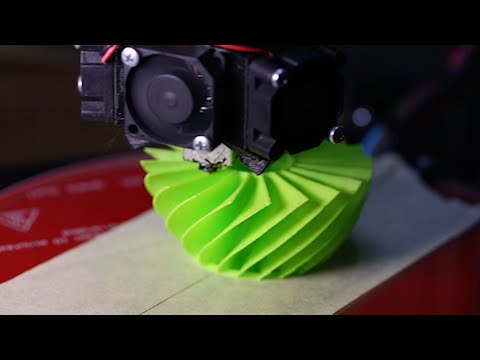

As 3D printing have evolved, a variety of technology and techniques have been used to improve the quality of printed objects. One such technology is the use of specific heaters and sensors within the printer that play a critical role in the success of the process.

TUTCO cartridge heaters, as small as 1/4” to 1/8” in diameter and 1” to 1 1/2” long, are used inside the 3D printer extrusion heads. These heaters are responsible for melting plastic material, which is then extruded in layers to create a 3D printed object. Different types of plastic require different temperatures, and these heaters can hold temperatures anywhere from 180°C for PLA plastic to 260°C for Pure PETG plastic.

In addition to cartridge heaters, a warm print bed is also necessary for some types of plastic material. Flat silicone rubber and Kapton heaters are used to create a warm print bed. A warm print bed helps prevent warping of the finished part and improves adhesion of the first printed layer to the bed itself, which reduces the severity of contraction of earlier printed layers and prevents part curling.

Thermocouple sensors are also being used in 3D printing to measure temperature. These sensors are available in a variety of configurations, including grounded or ungrounded junctions and different conductor materials such as type K and J. They also come with adaptors attached like threaded bushings or hex head bushings in stainless or brass. Leadwire lengths can vary as required and they are available with stainless steel braid or armor covering if necessary.

As 3D printing technology continues to advance, the use of specific heaters and sensors will become increasingly important to achieve the highest quality prints possible. TUTCO engineers will continue to develop leading edge solutions for this evolving application.